2025 Trends in Flexible Printed Circuit Boards: Innovations and Applications

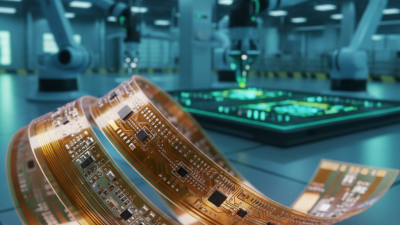

The flexible printed circuit board (FPCB) market is undergoing a significant transformation as we approach 2025, driven by rapid advancements in technology and a growing demand for innovative applications across various industries. According to a report by Research and Markets, the global flexible printed circuit board market is expected to reach approximately $30 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 10.4% from 2020 to 2025. This remarkable growth is fueled by the escalating use of FPCBs in consumer electronics, automotive applications, and healthcare devices, where miniaturization and flexibility are paramount.

Innovations in materials and manufacturing processes are paving the way for the next generation of FPCBs, enhancing their performance characteristics and expanding their applications. For instance, advancements in polyimide substrates and printing technologies are enabling the production of more complex circuit designs that can withstand harsh environmental conditions. According to an analysis by IDTechEx, the integration of FPCBs with emerging technologies such as IoT and wearable devices is set to revolutionize multiple sectors, presenting new opportunities for manufacturers and suppliers alike. As we delve deeper into the trends shaping this dynamic industry, it becomes essential to understand how these innovations will influence current and future applications of flexible printed circuit boards.

Emerging Technologies in Flexible Printed Circuit Boards for 2025

The year 2025 heralds significant advancements in

flexible printed circuit boards (FPCBs), driven by emerging technologies that enhance both performance and functionality.

One major trend is the integration of advanced materials,

including high-frequency laminates and biodegradable substrates, which not only improve signal integrity but also cater to

the growing demand for environmentally friendly solutions. This evolution aligns with industry efforts to create

sustainable technologies without compromising on performance.

Additionally, the rise of 5G technology and the

Internet of Things (IoT) is pushing the boundaries of design and application for FPCBs.

As devices become increasingly compact and multifaceted, innovations such as 3D printing and

nano-coating techniques are gaining traction. These technologies enable the development of

thinner, lighter, and more flexible circuit boards that can easily adapt to various applications, from

wearable devices to medical instruments. The ongoing research into

smart materials also promises to imbue FPCBs with self-healing capabilities and

enhanced durability, further broadening their possible uses in diverse sectors.

Key Innovations Driving Flexible PCB Development in 2025

In 2025, the landscape of flexible printed circuit boards (PCBs) is set to undergo significant transformations driven by several key innovations. One of the most notable advancements is the integration of advanced materials such as high-performance polymers and flexible substrates, which enhance durability while maintaining flexibility. This shift not only improves the reliability of PCBs in various applications but also allows for better thermal management, essential in high-density circuit designs.

Another trend to watch is the adoption of cutting-edge manufacturing techniques, including additive manufacturing and laser processing. These methods enable manufacturers to produce intricate designs with reduced waste and shorter lead times. As flexibility becomes paramount in evolving electronic devices—from wearables to medical implants—these innovations are crucial in meeting the demand for lightweight and adaptable components.

**Tips:** When considering flexibility and durability in PCB design, always prioritize materials that offer the best performance under stress. Additionally, keep an eye on emerging manufacturing technologies; they may present new avenues to optimize your production processes. Collaborating with suppliers who specialize in innovative components can also provide you with a competitive edge in your product offerings.

Sustainable Materials and Processes in Flexible Circuit Production

The evolving landscape of flexible printed circuit boards (FPCBs) is being significantly shaped by a commitment to sustainable materials and processes. As industries increasingly prioritize eco-friendly practices, manufacturers are exploring biodegradable substrates, non-toxic inks, and recyclable components. The integration of these sustainable materials not only reduces environmental impact but also aligns with consumer demand for greener products. This shift towards sustainability is not merely a trend; it is becoming a fundamental aspect of circuit production that could redefine industry standards.

**Tips:** When selecting materials for FPCB production, consider using suppliers that prioritize sustainable practices. Research the lifecycle of the materials to ensure minimal environmental impact, and advocate for the use of recycled or recyclable components in your designs.

In addition to materials, the production processes themselves are being optimized for sustainability. Innovations such as water-based adhesives and environmentally friendly etching techniques are emerging as alternatives to traditional, more harmful methods. These advancements not only lower emissions and waste but also enhance the overall efficiency of production. Transitioning to these sustainable processes can lead to cost savings and improved product durability, making them a smart choice for manufacturers and designers alike.

**Tips:** Always stay updated on the latest innovations in sustainable manufacturing processes. Networking with eco-conscious suppliers and attending industry conferences can provide valuable insights and foster collaboration towards greener solutions.

2025 Trends in Flexible Printed Circuit Boards: Innovations and Applications

Enhanced Applications of Flexible PCBs in Consumer Electronics

As consumer electronics continue to evolve, the role of flexible printed circuit boards (PCBs) is becoming increasingly significant. In 2025, we anticipate a surge in the application of flexible PCBs, driven by the demand for lightweight and compact devices. With innovations in materials and manufacturing techniques, these boards can now support more intricate designs while accommodating the slim profiles of modern gadgets. This shift allows for a seamless integration of technology into everyday consumer products, enabling features such as bendable displays and wearable devices that enhance user experience.

The enhanced applications of flexible PCBs in consumer electronics extend beyond mere aesthetics. They enable functionalities in devices that require flexible components, such as smartphones with curved screens and smartwatches that conform to the wrist. Additionally, the automotive industry is also experiencing benefits from flexible PCB technology, integrating them into advanced driver-assistance systems (ADAS) that require adaptability without sacrificing performance. As manufacturers continue to push the boundaries of design and functionality, the future landscape of consumer electronics will undoubtedly be shaped by the innovations in flexible PCB technology.

2025 Trends in Flexible Printed Circuit Boards: Innovations and Applications

| Application Area | Key Innovations | Growth Rate ( CAGR ) | Market Share (%) |

|---|---|---|---|

| Wearable Devices | High-density interconnections, improved flexibility | 15% | 25% |

| Smartphones | Thinner designs, enhanced thermal management | 10% | 30% |

| Tablets | Integration of multiple functions on a single board | 8% | 20% |

| IoT Devices | Increased miniaturization, advanced communication capabilities | 20% | 15% |

| Home Automation | Enhanced connectivity and network capabilities | 12% | 10% |

Future Trends in Integration and Miniaturization of Flexible Circuits

The future of flexible printed circuit boards (FPCBs) is poised for remarkable advancements, focusing on integration and miniaturization. As industries push for smaller, more efficient components, the flexibility and adaptability of FPCBs become essential. According to a recent industry report by MarketsandMarkets, the global flexible printed circuit board market is anticipated to expand at a CAGR of 10.4%, reaching USD 29.4 billion by 2025. This growth indicates a strong demand for innovative applications in consumer electronics, automotive, and medical devices.

Innovations such as advanced materials, including polyimide and polyethylene naphthalate, are paving the way for thinner and lighter circuit designs. These materials not only enhance performance but also improve durability under extreme conditions. Furthermore, integrated technologies, such as embedded components and 3D stacking, are vital trends that enable more complex functionalities within smaller footprints. This integration drives new applications, especially in wearables and IoT devices, where space and weight savings are critical.

Tips: When designing flexible circuits, prioritize the choice of materials to enhance performance and reliability. Additionally, keep an eye on developing technologies that can further miniaturize components while maintaining their functionality. Embracing these trends can lead to significant competitive advantages in the ever-evolving electronics landscape.

Related Posts

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

Exploring the Future of Electronics: How Flexible Printed Circuit Boards Will Revolutionize device Design in 2024

-

Understanding PCB Production: Essential Insights for Future Electronics Innovators

-

Top 5 Benefits of Using Flex Circuit Boards in Modern Electronics

-

2025 Guide: How to Choose the Best Flexible PCB Manufacturing Services

-

What is Circuit Board Design and How to Get Started with It