Top 5 Benefits of Using Flex Circuit Boards in Modern Electronics

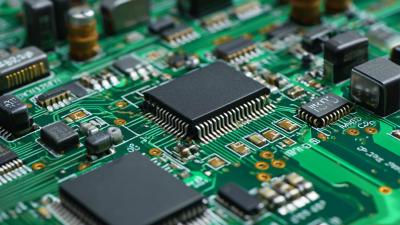

In the rapidly evolving field of electronics, the integration of innovative technologies has become vital for enhancing performance and functionality. Among these advancements, the flex circuit board has emerged as a game-changer. Dr. Emily Chen, a leading expert in flexible electronics, aptly stated, "Flex circuit boards not only optimize space and weight but also offer unparalleled design flexibility, pushing the boundaries of what electronic devices can achieve." This sentiment reflects the increasing reliance on flex circuit boards in modern applications, where their unique properties significantly contribute to miniaturization and efficiency.

The adoption of flex circuit boards in electronic design is driven by their numerous advantages, including lightweight construction, adaptability to complex shapes, and improved thermal management. As industries shift towards compact and multifunctional devices, these boards are redefining conventional manufacturing processes and enabling innovative solutions across various sectors. Understanding the top benefits of flex circuit boards is essential for engineers and designers alike, as they seek to leverage this technology to meet the demands of contemporary electronics.

Advantages of Flex Circuit Boards for Compact Designs in Electronics

Flex circuit boards have become essential in modern electronics, particularly for compact designs. The ability to bend, twist, and fold makes them ideal for smartphones, wearables, and other space-constrained devices. According to a report by the markets research firm Yole Développement, the global market for flexible circuits is expected to reach $30 billion by 2026, driven by the demand for miniaturized, lightweight components in consumer electronics. These characteristics not only reduce the overall size of devices but also improve their performance and reliability.

Tips: When designing with flex circuits, consider the minimum bend radius to avoid compromising the board's integrity. Additionally, use simulation tools to predict how the circuit will perform under stress and flexing conditions.

Another advantage of flex circuit boards is their exceptional thermal management capabilities. They can dissipate heat more effectively than traditional rigid boards due to their high surface area and proximity to heat-generating components. Research indicates that flexible circuits can achieve thermal conductivity levels as high as 50 W/mK, enhancing the longevity and performance of electronic devices.

Tips: Always ensure that flex circuits are compatible with existing assembly processes to streamline production and maintain quality standards. Emphasizing this compatibility can significantly reduce manufacturing costs and time.

Top 5 Benefits of Using Flex Circuit Boards in Modern Electronics

| Benefit | Description | Application Examples |

|---|---|---|

| Space Efficiency | Flex circuit boards can be bent and shaped to fit into tight spaces, allowing for more compact designs. | Smartphones, medical devices |

| Lightweight | They are lighter than traditional rigid circuit boards, contributing to the overall reduction in device weight. | Wearable technology, drones |

| Durability | Flex circuits are less likely to break under stress compared to rigid boards, increasing lifespan and reliability. | Automotive electronics, industrial equipment |

| Design Flexibility | They allow for innovative designs that can include multiple layers and complex geometries. | Consumer electronics, IoT devices |

| Cost-Effectiveness | While initial costs may be higher, their efficiency can lead to lower assembly costs and reduced overall production expenses. | Mass production applications, complex assemblies |

Enhanced Durability and Reliability of Flexible Circuits

Flexible circuit boards have emerged as a crucial technological advancement in modern electronics, primarily due to their enhanced durability and reliability. Unlike traditional rigid circuit boards, flex circuits can bend, twist, and fold without compromising their integrity. This characteristic is particularly valuable in portable and compact devices where space is limited. As electronic components become increasingly miniaturized, the ability of flexible circuits to withstand mechanical stress becomes an indispensable asset, ensuring that devices remain functional over time, even in demanding environments.

Moreover, the materials used in flexible circuit boards contribute significantly to their reliability. These circuits are often made from robust polymers that offer resistance to environmental factors such as moisture, heat, and chemicals. This resistance not only extends the lifespan of the devices but also reduces the likelihood of failure, which is critical in applications ranging from medical devices to automotive systems. As industries continue to prioritize efficiency and longevity in their designs, the enhanced durability of flexible circuits positions them as a preferred choice for next-generation electronic solutions.

Top 5 Benefits of Using Flex Circuit Boards in Modern Electronics

The Role of Flex Circuit Boards in Reducing Weight and Size

Flex circuit boards are increasingly vital in modern electronics, particularly due to their capability to reduce weight and size. This revolutionary technology allows designers to create compact and lightweight devices without compromising on performance.

As electronic components continue to miniaturize, the use of flex circuit boards enables manufacturers to meet the growing demand for portable electronics, ensuring that devices remain both functional and easy to transport.

Flex circuit boards are increasingly vital in modern electronics, particularly due to their capability to reduce weight and size. This revolutionary technology allows designers to create compact and lightweight devices without compromising on performance.

As electronic components continue to miniaturize, the use of flex circuit boards enables manufacturers to meet the growing demand for portable electronics, ensuring that devices remain both functional and easy to transport.

Moreover, by integrating flex circuit boards, companies can streamline their production processes. Unlike traditional rigid boards, these flexible circuits can be manipulated to fit into tight spaces and complex geometries. This adaptability not only results in more efficient use of materials but also leads to significant reductions in assembly time and costs.

As seen across various industries, from consumer electronics to medical devices, the benefits of using flex circuits are paving the way for innovative designs that prioritize portability while maintaining high performance.

Cost-Effectiveness of Manufacturing Flexible Circuit Solutions

The cost-effectiveness of manufacturing flexible circuit solutions has become increasingly apparent as industries seek innovative methods to enhance efficiency and reduce production expenses. Recent data indicates that the global printed electronics market is expected to grow from USD 19.92 billion in 2025 to nearly USD 83.77 billion, showcasing a significant demand for cost-efficient flexible electronics. This surge is driven by advancements in fabrication techniques, such as the use of laser-induced graphene, which allows for the creation of flexible circuits on demand, facilitating lower manufacturing costs and shorter lead times.

In addition to reducing expenses, flexible circuit boards offer the advantage of integration with emerging technologies. For instance, bio-microsystem integration and lab-on-PCB innovations have transformed traditional lab setups into compact, cost-effective solutions for chemical analysis. By overcoming the challenges posed by power and scalability in data centers, flexible circuits enable efficient heat management and power distribution, further contributing to their cost-effective appeal. As the market for flexible electronics continues to expand, manufacturers are increasingly recognizing the potential of these solutions to meet modern electronic demands while operating within budget constraints.

Versatility in Application: Diverse Uses of Flex Circuit Boards in Tech

Flex circuit boards are revolutionizing the landscape of modern electronics, offering unparalleled versatility in application across various sectors. According to a report from the International Data Corporation (IDC), the global flexible printed circuit (FPC) market is projected to grow at a compound annual growth rate (CAGR) of 9.8% from 2022 to 2029. This growth is largely driven by the increasing adoption of flexible circuits in smartphones, wearables, and medical devices, which require lightweight and compact solutions without compromising performance.

One of the key advantages of flex circuit boards is their ability to conform to various shapes and sizes, making them ideal for innovative designs. For instance, in the automotive industry, flex circuits are utilized in advanced driver-assistance systems (ADAS), enhancing functionalities such as adaptive cruise control and lane-keeping assistance. A report from ResearchAndMarkets highlights that the automotive segment is expected to account for over 35% of the FPC market by 2025, reflecting the technology's diverse applications in enhancing vehicle intelligence. Furthermore, the healthcare sector is increasingly integrating flex circuits in wearable monitoring devices, providing real-time health data while ensuring comfort and mobility for users.

Related Posts

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics

-

Understanding PCB Production: Essential Insights for Future Electronics Innovators

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics