Top 10 Benefits of Using Flex PCB Boards in Modern Electronics

In the rapidly evolving world of electronics, the demand for compact and efficient designs has led to significant advancements in circuit board technology. Among these, the "flex PCB board" has emerged as a revolutionary solution, offering unrivaled flexibility, lightweight construction, and the ability to conform to intricate shapes. According to Dr. Emily Chen, an expert in flexible electronics and a lead researcher at the Flexible Circuits Institute, "Flex PCB boards not only enhance the adaptability of devices but also play a crucial role in the miniaturization of modern electronics."

As we delve into the top 10 benefits of using flex PCB boards, it becomes evident that their unique characteristics are transforming traditional electronic design paradigms. From consumer gadgets to medical devices, these flexible printed circuit boards provide designers with the freedom to explore innovative layouts that were previously constrained by the rigidity of conventional PCBs. The incorporation of flex PCBs in product development not only optimizes space but also results in lighter and more efficient devices that cater to the needs of today's tech-savvy consumers.

This exploration aims to highlight the myriad advantages of flex PCB technology, showcasing how it contributes to enhanced performance, improved reliability, and greater design versatility in modern electronics. As we continue to push the boundaries of technological advancement, understanding the benefits of flex PCB boards becomes essential for engineers and designers aiming to stay ahead in a highly competitive market.

Advantages of Flex PCB Boards Over Traditional Rigid PCBs

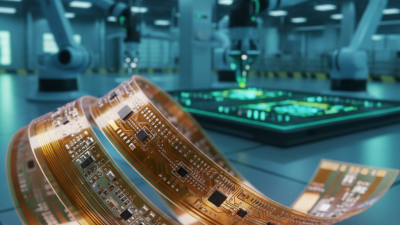

Flex PCB boards have gained significant traction in modern electronics, primarily due to their unique advantages over traditional rigid PCBs. One of the most notable benefits is their ability to bend and conform to different shapes, allowing for more creative and efficient designs. This flexibility enables manufacturers to create compact and lightweight devices without compromising on functionality or performance. As a result, they can fit into tight spaces that rigid boards simply cannot.

Furthermore, flex PCBs offer improved durability and reliability, particularly in dynamic applications where movement is frequent. Unlike rigid boards, which are prone to cracking under stress, flex designs can endure repeated bending without damage. This resilience not only extends the lifespan of electronic products but also reduces the risk of failure in critical applications. Additionally, the reduced number of interconnections in flex PCBs minimizes the chances of mechanical failure, further enhancing their appeal over traditional counterparts.

Top 10 Benefits of Using Flex PCB Boards in Modern Electronics

This chart illustrates the advantages of using Flex PCB boards over traditional rigid PCBs across various dimensions.

Enhanced Design Flexibility with Flex PCB Technology

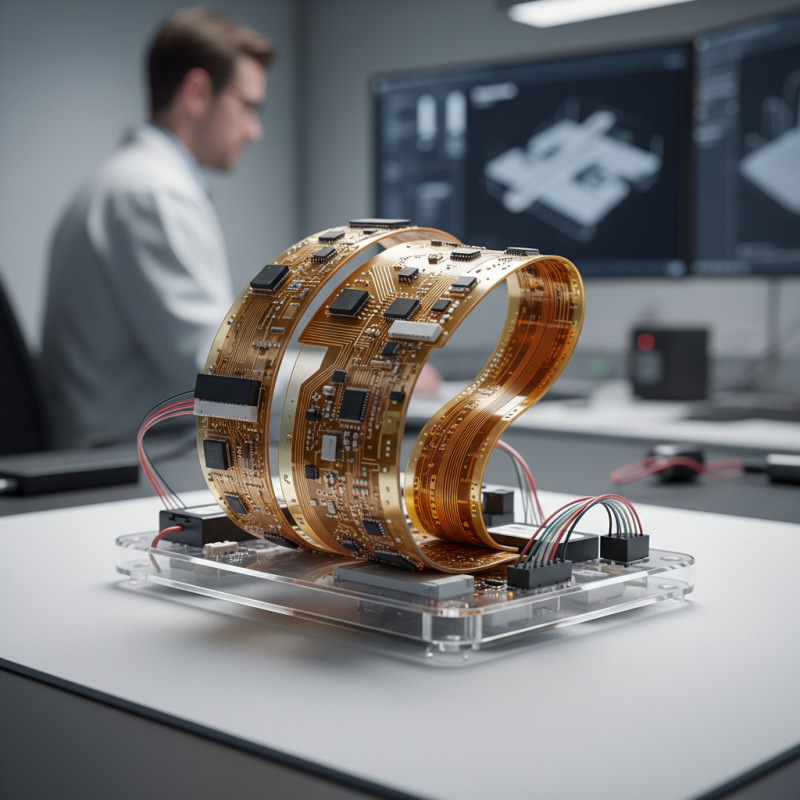

Flexible printed circuit boards (Flex PCBs) offer unparalleled design flexibility, allowing engineers and designers to create compact and intricate electronic layouts that were previously difficult to achieve with traditional rigid boards. The ability to bend, twist, and fold these circuits enables a new wave of innovation, especially in the miniaturization of electronic devices. This flexibility not only contributes to lighter products but also improves space utilization within devices, making Flex PCBs ideal for the evolving demands of modern electronics.

Moreover, the integration of Flex PCB technology promotes seamless interconnection in multilayer designs and supports various geometries essential for advanced applications. For instance, in wearable technology and IoT devices, Flex PCBs can be effortlessly integrated into unconventional shapes, enhancing ergonomics and user experience. This adaptability represents a significant advancement in electronic design, allowing for rapid prototyping and reduced assembly complexity. As industries continue to prioritize efficiency and performance, the role of Flex PCBs in enabling innovative design solutions cannot be overstated.

Improved Space Utilization in Compact Electronics

Flexible printed circuit boards (Flex PCBs) have become a game changer in modern electronics, particularly in enhancing space utilization within compact devices. Unlike traditional rigid boards, Flex PCBs can easily bend, twist, and fit into tight spaces. This flexibility allows designers to create smaller and more efficient devices without compromising performance. As a result, many electronic products, from smartphones to wearable technology, benefit from this space-efficient design, leading to sleeker devices that are more comfortable and practical for users.

Tips: When designing with Flex PCBs, consider the orientation of components to maximize space efficiency. Grouping components in a way that minimizes trace lengths can also help reduce size and improve performance. Moreover, utilizing multilayer designs can further enhance functionality without increasing the board's footprint.

In addition to their superior space utilization, Flex PCBs facilitate better heat dissipation, an essential factor in compact electronic devices. By distributing heat more evenly, these boards can prevent overheating and enhance the longevity of the device. Moreover, the lightweight nature of Flex PCBs contributes to the overall reduction in weight, making them ideal for portable electronics. Emphasizing these features ensures that manufacturers can meet the growing consumer demand for compact and efficient technology.

Increased Durability and Reliability of Flex PCBs

Flex PCB boards have emerged as a cornerstone of modern electronics, largely due to their increased durability and reliability compared to traditional rigid boards. One of the primary advantages of flexible PCBs is their ability to withstand mechanical stress and environmental factors. Unlike rigid boards, flex PCBs can bend and twist without compromising their integrity, making them ideal for applications in compact and dynamic devices such as wearable technology and mobile gadgets. This flexibility helps prevent the microfractures that can lead to failures in conventional boards, enhancing the overall lifespan of electronic products.

Moreover, the manufacturing techniques used in producing flex PCBs contribute to their reliability. These boards are often designed with multiple layers that can effectively distribute heat and electrical loads, minimizing the risk of thermal fatigue and electrical failures. Additionally, the materials used in flex PCB construction, such as polyimide, boast excellent thermal stability and resistance to moisture and chemicals. This makes them suitable for harsh conditions often encountered in automotive and industrial applications. As a result, using flex PCBs not only ensures better performance but also reduces maintenance costs, ultimately leading to improved user satisfaction in various electronic devices.

Top 10 Benefits of Using Flex PCB Boards in Modern Electronics - Increased Durability and Reliability of Flex PCBs

| Benefit | Description | Impact on Electronics |

|---|---|---|

| Increased Flexibility | Flex PCBs can be bent and shaped to fit into compact spaces. | Allows for innovative designs in modern devices. |

| Reduced Weight | Flex PCBs are lighter compared to traditional rigid boards. | Enhances portability of electronic devices. |

| Higher Density Integration | Allows for more components to be placed in a smaller area. | Increases functionality of compact devices. |

| Improved Thermal Management | Flex PCBs can dissipate heat more efficiently. | Enhances the reliability and lifespan of electronics. |

| Reduced Manufacturing Costs | Simplifies assembly processes, reducing labor time. | Lower overall production costs for manufacturers. |

| Enhanced Reliability | Fewer solder joints and connections reduce the risk of failure. | Increases the longevity of products in use. |

| Vibration Resistance | Designed to withstand vibrations in applications. | Ideal for automotive and industrial electronics. |

| Environmental Resistance | Materials used are often resistant to moisture and chemicals. | Suitable for rugged applications and tough environments. |

| Design Versatility | Adaptable to various shapes and configurations. | Facilitates creative and custom designs for products. |

| Better Signal Integrity | Shorter pathways reduce loss and interference. | Enhances performance in high-frequency applications. |

Cost-Effectiveness and Scalability of Flex PCB Manufacturing

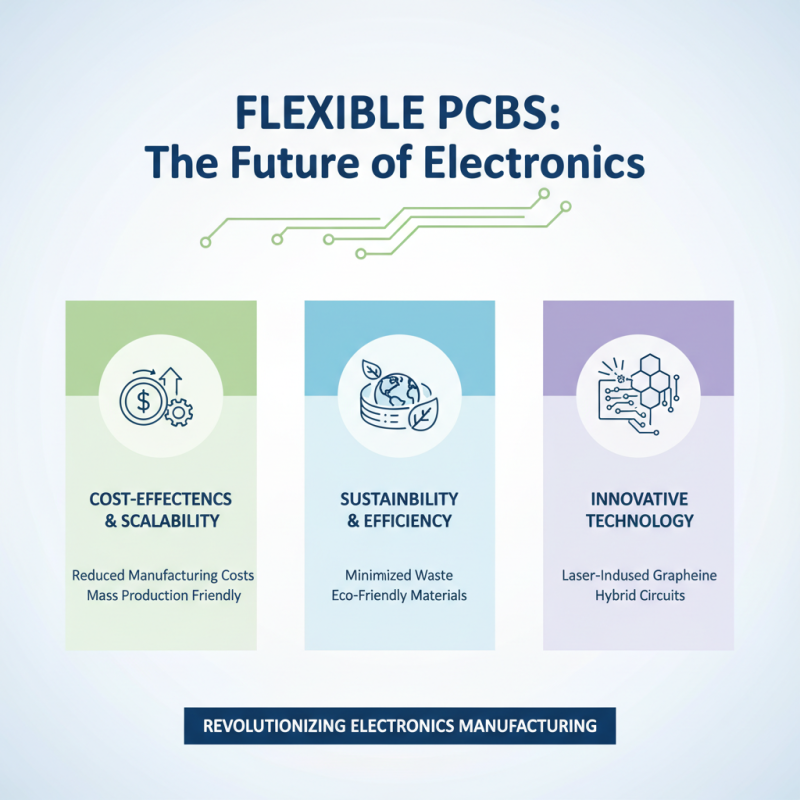

The use of flexible PCB boards in modern electronics has revolutionized manufacturing processes, particularly when it comes to cost-effectiveness and scalability. As advancements in technologies like laser-induced graphene unfold, manufacturers can create hybrid circuits that are not only affordable but also environmentally friendly. By minimizing waste and reducing the overall environmental impact, these innovative methods contribute significantly to the sustainability goals of the electronics industry.

When considering the scalability of flex PCB manufacturing, businesses can capitalize on the growing demand for products that incorporate micro-total analysis systems (µTAS) and Lab-on-PCB technologies. These systems allow for compact, efficient designs that streamline processes while retaining functionality. As the market for printed flexible electronics is projected to expand significantly, companies can benefit from adapting quickly to these eco-friendly and effective manufacturing techniques.

**Tips:** Embrace new technologies like laser-induced graphene to reduce costs and environmental impact while manufacturing flexible circuits. Additionally, staying informed about market trends will aid in making strategic decisions that align with future demands. Lastly, prioritize the integration of sustainable practices to enhance both profitability and ecological responsibility in your electronics production processes.

Related Posts

-

Exploring the Future of Electronics: How Flexible Printed Circuit Boards Will Revolutionize device Design in 2024

-

2025 Guide: How to Choose the Best Flexible PCB Manufacturing Services

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

What is Circuit Board Manufacturing? A Comprehensive Guide for Beginners

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics