Top 10 Benefits of Using Flexible PCB Boards in Modern Electronics

As the demand for compact and efficient electronic devices continues to grow, the importance of flexible PCB boards (Printed Circuit Boards) in modern electronics cannot be overstated. According to Dr. Anne Peters, a leading expert in flexible electronics, "The versatility of flexible PCB boards has revolutionized the way we design and manufacture electronic devices." Their unique ability to bend, twist, and fit into unconventional spaces allows engineers and designers to push the boundaries of innovation, enabling the creation of lightweight and portable products.

Flexible PCB boards offer a multitude of benefits that cater to various industry needs, ranging from consumer electronics to medical devices. Their ability to conform to intricate shapes not only optimizes the overall design but also enhances durability and reliability in challenging environments. As technology advances toward miniaturization, the role of flexible PCBs will continue to expand, setting the stage for future breakthroughs in electronic design and functionality. Embracing these boards not only simplifies assembly but also significantly reduces the risk of failure, making them an essential component in the landscape of modern electronics.

Advantages of Flexible PCB Boards in Electronic Design

Flexible PCB boards have revolutionized electronic design, offering significant advantages over traditional rigid counterparts. One of the primary benefits is their lightweight and compact nature, which allows design engineers to create slimmer and more portable devices. This flexibility not only facilitates the integration of multiple components in limited spaces but also enables complex geometries that conform to various shapes and environments, enhancing overall design versatility.

Moreover, flexible PCBs offer improved durability, as they can withstand bending and twisting without compromising performance. This inherent resilience makes them ideal for applications in dynamic settings, such as wearable technology and mobile devices, where movement is constant. Additionally, their ability to reduce the number of interconnections leads to simplified assembly, minimizing potential points of failure and contributing to more reliable electronic systems. As designers increasingly prioritize efficiency and functionality, the advantages provided by flexible PCB boards continue to shape the landscape of modern electronics.

Top 10 Benefits of Using Flexible PCB Boards in Modern Electronics

| Benefit | Description |

|---|---|

| Space Saving | Flexible PCBs can be shaped to fit into tight spaces, maximizing design efficiency. |

| Lightweight | They are significantly lighter than rigid boards, contributing to overall device portability. |

| Durability | Flexible PCBs are resistant to vibrations and stress, enhancing product lifespan. |

| Reduced Assembly Costs | Their design can reduce the number of components needed, lowering assembly time and costs. |

| Thermal Management | Flexible PCBs can effectively manage heat due to their materials and design capabilities. |

| Design Versatility | They allow for complex layouts and can integrate easily into various shapes and designs. |

| High Circuit Density | Flexible PCBs can accommodate a higher density of circuits compared to rigid boards. |

| Environmental Resistance | They can be manufactured for resistance to moisture, chemicals, and extreme temperatures. |

| Enhanced Performance | Flexible PCBs can improve performance due to better signal integrity and lower inductance. |

| Easier Integration | They can be easily incorporated into complex devices without needing separate housing. |

Enhanced Space Efficiency Through Flexible PCB Integration

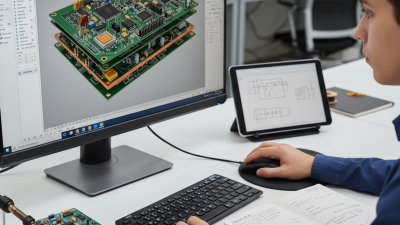

Flexible PCB boards have revolutionized the design and functionality of modern electronics, especially in enhancing space efficiency. Their ability to conform to various shapes and environments allows for intricate layouts that traditional rigid boards cannot accommodate. This adaptability enables manufacturers to create compact designs that optimize available space within devices, critical in applications ranging from smartphones to medical equipment. By integrating flexible PCBs, engineers can pack more functionality into smaller enclosures, effectively reducing the overall footprint of electronic devices.

Moreover, the reduction in size is complemented by improved airflow and heat dissipation properties. Traditional circuit boards can trap heat in constricted spaces, leading to performance issues and decreased reliability. In contrast, flexible PCBs facilitate better thermal management due to their design flexibility, allowing for strategic placement of heat-sensitive components. This integration not only enhances the durability and longevity of the electronics but also contributes to a sleek and modern aesthetic, making them highly desirable in today's market. Overall, the enhanced space efficiency provided by flexible PCBs is a compelling advantage in the push toward more sophisticated and streamlined electronic solutions.

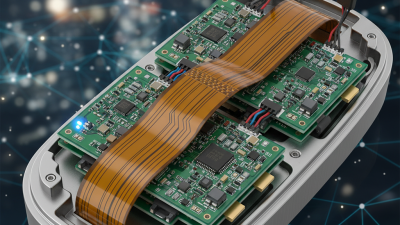

Improved Durability: Resilience of Flexible PCBs Under Stress

Flexible PCB boards have emerged as a pivotal innovation in modern electronics, particularly due to their remarkable durability. When subjected to stress, these boards demonstrate an exceptional resistance that traditional rigid boards simply cannot match. This resilience allows for greater design flexibility, enabling devices to be more compact and adaptable. In applications where components endure substantial bending or twisting, such as in wearable technology or portable devices, using flexible PCBs ensures longevity and reliability in performance.

Tips for enhancing the durability of flexible PCBs include using appropriate materials that can withstand environmental factors like temperature and humidity. Additionally, proper handling during installation and assembly can prevent physical damage that might compromise their resilient properties. Maintaining a meticulous design process that includes strain relief features can also significantly enhance the lifespan of the circuit boards.

Investing in quality manufacturing techniques is crucial for ensuring maximum durability. It’s advisable to work closely with suppliers to understand the specifications of the materials used in flexible PCBs. This collaboration can yield better results in performance under stress and ultimately lead to a more robust electronic device.

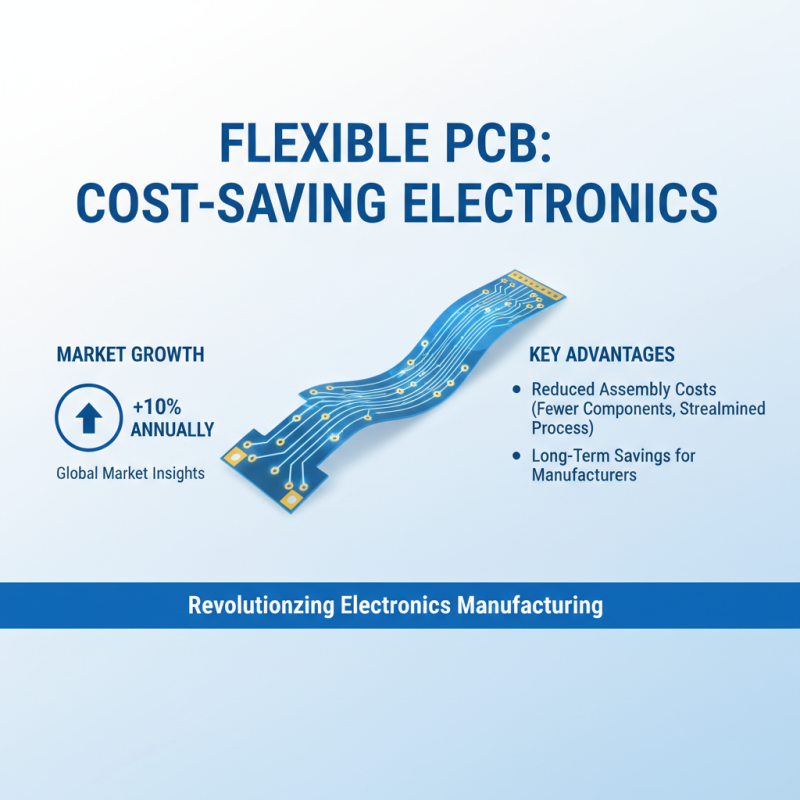

Cost-Effectiveness: Long-Term Savings from Flexible PCB Solutions

Flexible PCB boards are revolutionizing the electronics industry, particularly due to their cost-effectiveness. A report by the Global Market Insights indicates that the flexible PCB market is projected to witness a growth rate exceeding 10% annually over the next several years. This surge can be attributed to the long-term savings provided by flexible PCB solutions. Unlike traditional rigid boards, flexible PCBs can reduce assembly costs by minimizing the number of components needed and streamlining the manufacturing process. This can lead to substantial savings for manufacturers, especially in high-volume production scenarios.

One of the major financial benefits of using flexible PCBs is their ability to enable compact designs. As devices become smaller and more sophisticated, the reduction in board size allows for easier integration into devices, which not only cuts material costs but also reduces shipping expenses. Additionally, with the increasing complexity of electronic devices, using flexible PCBs can lead to lower overall system costs, including maintenance and repair, since they are often more reliable and resilient to stress or environmental factors.

Tips: When considering flexible PCBs for your projects, prioritize the design phase to maximize the space-saving potential. Collaborating closely with your PCB manufacturer during this stage can yield innovative solutions tailored to your needs, ultimately enhancing cost savings. Additionally, regular assessments of your production process can identify areas where flexible PCBs could contribute to efficiency and cost reduction.

Versatility in Application: Flexible PCBs in Various Industries

Flexible printed circuit boards (FPCBs) have become a crucial component in various industries, owing to their versatility and adaptability in modern electronics. According to industry reports, the global flexible PCB market size was valued at approximately $20 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of around 10% over the next five years. This growth can be attributed to the increasing demand for lightweight and space-saving electronic devices across sectors such as healthcare, automotive, and consumer electronics.

In the healthcare industry, flexible PCBs enable the development of advanced medical devices, including wearable health monitors and diagnostic equipment. Their compact design allows for intricate circuit layouts that can conform to the unique shapes of medical devices, enhancing patient comfort and usability. Similarly, in the automotive sector, the trend towards smart vehicles is driving the adoption of flexible PCBs for applications such as advanced driver-assistance systems (ADAS) and in-car entertainment systems. These boards not only facilitate the integration of multiple functionalities into a single unit but also improve reliability and durability in harsh operating conditions.

Furthermore, the consumer electronics space has seen a surge in flexible PCB usage, particularly in smartphones, tablets, and other portable devices. This technology supports innovation in form factors, leading to thinner and lighter products that cater to consumer preferences without sacrificing performance. As the demand for multifunctional devices continues to rise, flexible PCBs will play an increasingly important role in shaping the future of electronics across various industries.

Top 10 Benefits of Using Flexible PCB Boards in Modern Electronics

Related Posts

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

2025 Guide: How to Choose the Best Flexible PCB Manufacturing Services

-

2025 How to Choose the Right Flex Circuit Board for Your Projects

-

How to Choose the Right Flex PCB Board for Your Project Needs

-

How to Design a Printed Circuit Board for Beginners in Easy Steps

-

What is Rigid Flex Rigid PCB and How it Benefits Modern Electronics