Top 10 Benefits of Using PCB Boards in Electronics Manufacturing

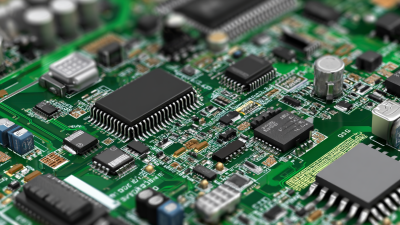

In the realm of electronics manufacturing, the significance of pcb boards cannot be overstated. These crucial components serve as the backbone of various electronic devices, enabling intricate circuitry and fostering efficient communication between different components. With the rapid advancement of technology, the demand for reliable and effective manufacturing processes has surged, making the adoption of pcb boards increasingly essential for engineers and manufacturers alike.

The benefits of utilizing pcb boards are multifaceted, encompassing aspects such as improved durability, customizable design options, and enhanced thermal management. By offering a stable platform for electronic components, pcb boards enhance the overall performance and longevity of devices. Moreover, their high-density design facilitates the miniaturization of products, allowing for more compact and efficient device configurations. As we explore the top advantages of incorporating pcb boards into electronics manufacturing, it becomes evident that these versatile tools not only streamline production but also pave the way for innovative designs and enhanced functionality in modern electronics.

Benefits of PCB Boards in Reducing Manufacturing Costs by 30%

The use of PCB boards in electronics manufacturing has become a cornerstone of modern production techniques, significantly contributing to cost efficiency. One of the most compelling advantages is their ability to reduce manufacturing costs by an impressive 30%. This reduction is primarily achieved through the streamlined production processes that PCBs facilitate. By integrating multiple electronic components onto a single board, manufacturers can minimize assembly time, reduce labor costs, and decrease the need for expensive materials, which altogether contribute to a more economical production cycle.

In addition to lowering costs, PCB boards enhance the overall quality and reliability of electronic products. Their compact design allows for better organization and minimizes the risk of errors during assembly. By utilizing advanced software for PCB design, manufacturers can also optimize layouts, ensuring efficient use of space and materials. This precision not only leads to further cost savings but also reduces waste, aligning manufacturing practices with sustainable development goals.

Ultimately, the adoption of PCB technology not only serves immediate financial benefits but also fosters long-term efficiency in the electronics sector.

Enhanced Design Flexibility: Meeting Complex Electronic Demands

In the fast-evolving electronics manufacturing landscape, the demand for enhanced design flexibility is paramount.

PCB boards serve as the backbone of most electronic devices, accommodating increasingly complex circuitry without compromising on size or efficiency.

According to a recent industry report by Research and Markets, the global printed circuit board market is projected to reach over $80 billion by 2026, primarily driven by

advancements in miniaturization and smart technology integration. This surge highlights the importance of PCBs in meeting intricate electronic demands across various applications, from

consumer electronics to aerospace.

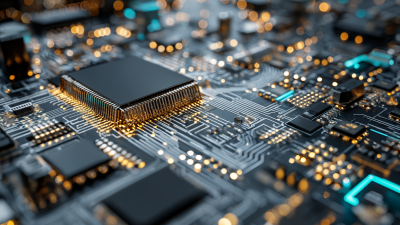

One of the key advantages that PCBs offer is their ability to support

multi-layer designs that allow for densely packed and highly functional circuits.

This capability enables engineers to innovate and incorporate features that respond to market needs without being constrained by traditional design limitations.

For instance, the use of HDI (High-Density Interconnector) technology has been found to improve circuit density by as much as 30%

compared to conventional PCBs, thereby facilitating the development of compact and efficient devices.

Additionally, the adaptability of PCBs allows for rapid prototyping and iteration, significantly reducing time-to-market and enabling companies to stay competitive in a technology-driven field.

Improved Reliability: PCB Boards Lead to a 20% Decrease in Failures

Printed Circuit Boards (PCBs) have become an essential component in the landscape of electronics manufacturing, particularly due to their significant impact on reliability. A recent industry report highlights that the implementation of PCB boards can lead to a remarkable 20% decrease in electronic failures. This improvement in reliability stems from several key factors, including the precise arrangement of components and the reduction of wiring errors, both of which are critical in complex electronic assemblies.

Additionally, the durability and robustness of PCB boards enhance long-term performance, reducing the frequency of repairs and replacements. According to a study conducted by the IPC-Association Connecting Electronics Industries, the reduction in failure rates not only contributes to improved product reliability but also lowers overall lifecycle costs for manufacturers. As companies face mounting pressures to produce high-quality electronic devices at competitive prices, the shift towards using PCBs has proven to be a strategic advantage, allowing them to meet industry standards and consumer expectations effectively.

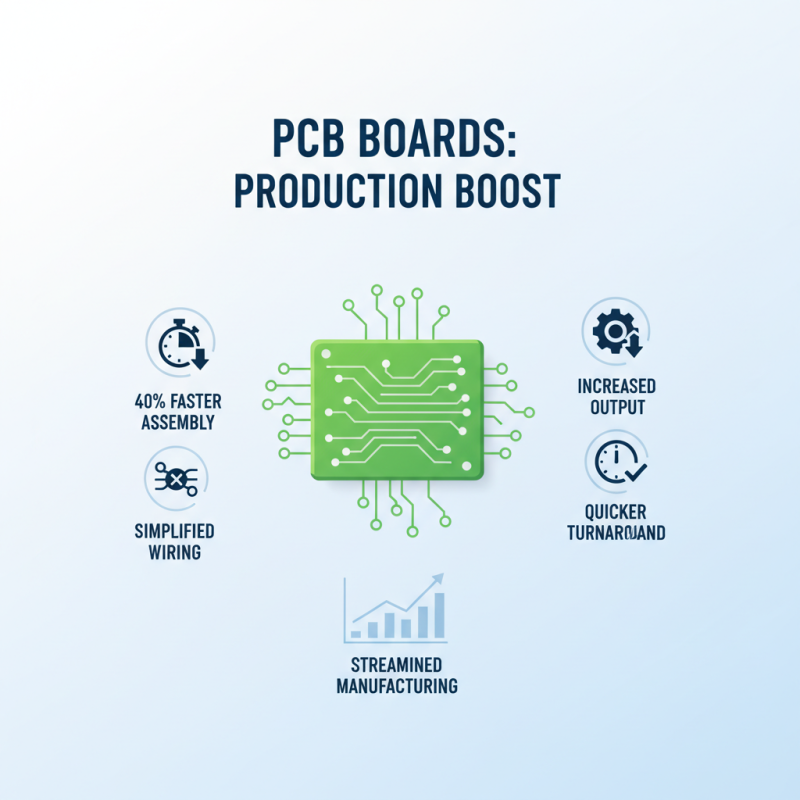

Increase in Production Efficiency: Accelerating Assembly Times by 40%

The use of PCB boards in electronics manufacturing offers a significant boost in production efficiency, particularly when it comes to assembly times. By streamlining the design and layout of electronic components, PCB boards enable manufacturers to reduce the time required for assembly by as much as 40%. This acceleration is primarily attributed to the ability to integrate multiple electronic components onto a single board, which minimizes the complexity of wiring and optimizes the overall assembly process. As a result, teams can allocate their time and resources more effectively, leading to quicker turnaround times and increased output.

Furthermore, the standardized nature of PCB manufacturing contributes to this efficiency. With simplified assembly processes, workers can be trained more quickly, and new personnel can seamlessly integrate into existing workflows. This not only enhances productivity but also ensures a higher consistency in quality. As assembly times decrease, it allows manufacturers to respond more agilely to market demands and fluctuations in consumer preferences, maintaining a competitive edge in a fast-paced industry. Embracing PCB technology thus becomes a strategic imperative for manufacturers aiming to enhance their operational efficiency and overall profitability.

Support for Eco-Friendly Practices: Minimizing Waste in Electronics Production

The electronics manufacturing industry is increasingly embracing environmentally friendly practices, with PCB boards playing a crucial role in minimizing waste. These boards are designed to be efficient and resource-conservative, allowing manufacturers to optimize the use of raw materials. By implementing advanced design techniques and utilizing high-quality materials, PCB production can significantly reduce excess scrap and defective components, leading to less waste generated during the manufacturing process.

Moreover, the longevity and durability of PCB boards contribute to eco-friendly practices. Their robust design ensures that electronic products are reliable and have a longer lifespan, which in turn reduces the frequency of replacements and disposals. This characteristic minimizes the environmental impact associated with discarded electronics, commonly known as e-waste. By making the shift to more sustainable PCB designs, manufacturers can not only meet regulatory requirements but also promote a greener future in electronics production.

Top 10 Benefits of Using PCB Boards in Electronics Manufacturing

This chart illustrates the top 10 benefits of using PCB boards in electronics manufacturing, highlighting their contributions to minimizing waste and supporting eco-friendly practices, along with other key advantages.

Related Posts

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics

-

Understanding PCB Production: Essential Insights for Future Electronics Innovators

-

Top 7 Most Innovative Techniques in Circuit Board Production You Need to Know