2025 How to Choose the Best Flexible PCBs for Your Project

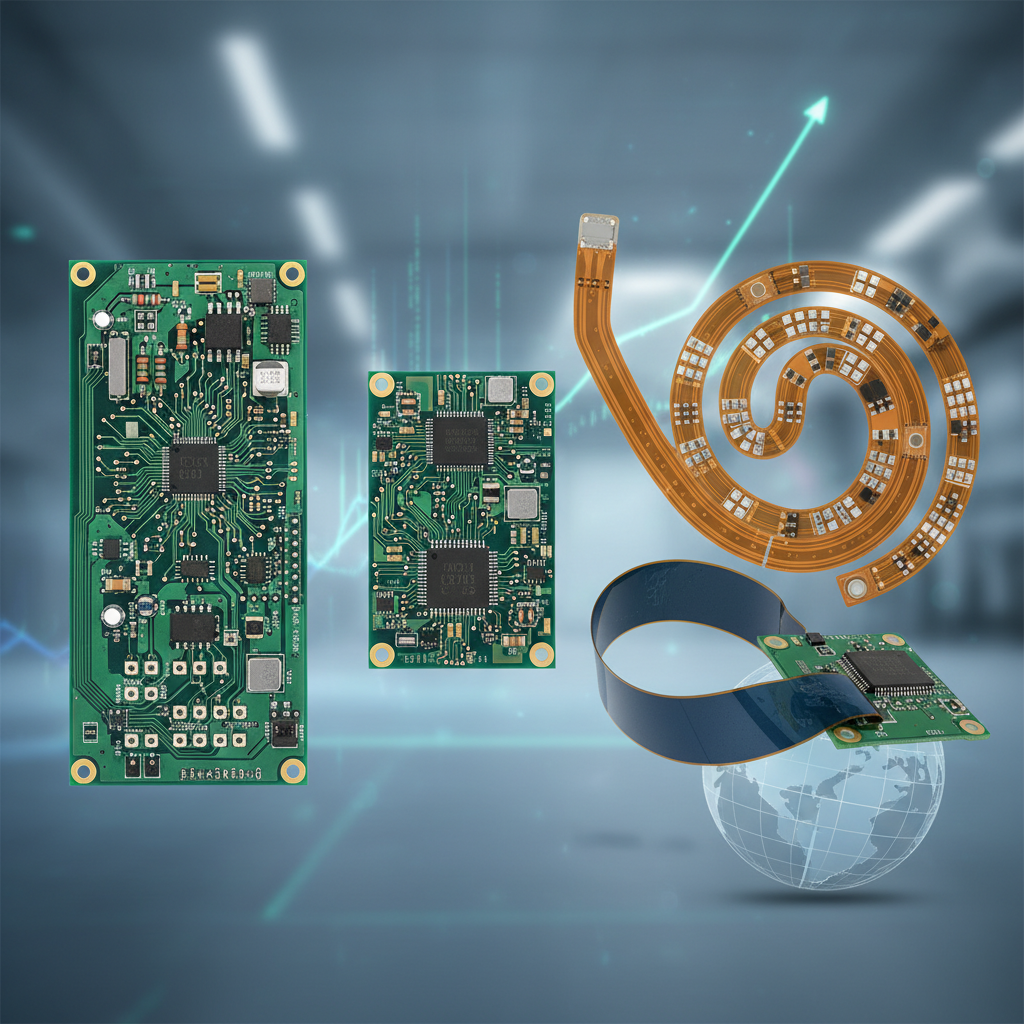

In the rapidly evolving world of electronics, the demand for more innovative and compact designs has led to a significant rise in the use of flexible printed circuit boards, commonly known as flex PCBs. As we approach 2025, it becomes increasingly essential for designers and engineers to navigate the myriad options available to ensure they select the best flex PCBs that align with their project requirements. This choice can profoundly impact not only the functionality but also the performance and reliability of electronic devices.

Choosing the right flexible PCBs involves considering various critical factors, such as material composition, thickness, and manufacturing capabilities. As projects become more complex, understanding these factors becomes paramount for achieving optimal results. In this guide, we will explore the top 10 flexible PCBs of 2025, offering insights into their unique features, advantages, and applications. This will enable engineers and designers to make informed decisions that enhance their projects while optimizing cost and efficiency. Whether you are working on a consumer electronics project or a specialized industrial application, understanding how to select the best flex PCBs is crucial for success in the competitive landscape of modern electronics.

Understanding the Importance of Flexible PCBs in Modern Electronics

Flexible printed circuit boards (PCBs) have become essential in modern electronics, driving innovation across various sectors. The global flexible battery market was estimated at approximately $156.3 million in 2023, with a remarkable compound annual growth rate (CAGR) projected at 23.75% from 2024 to 2031. This growth underscores the increasing reliance on flexible PCBs, which offer design flexibility, weight savings, and enhanced performance in compact electronic devices.

The importance of flexible PCBs goes beyond mere adaptability. They facilitate advanced applications, such as wearable technology and IoT devices, by allowing for complex circuits to be embedded in lightweight, space-efficient formats. As electronics continue to shrink in size while increasing in functionality, the role of flexible PCBs becomes even more critical. Their ability to withstand dynamic bending and twisting without compromising performance makes them an ideal choice for the ever-evolving landscape of modern electronics. Companies must prioritize selecting the right flexible PCB technology for their projects to stay competitive in this rapidly growing market.

Key Factors Influencing the Selection of Flexible PCBs for Your Projects

When selecting flexible printed circuit boards (PCBs) for your projects, several key factors significantly influence the decision-making process. One important consideration is the material composition of the flexible PCB. According to a report by MarketsandMarkets, the flexible PCB market is anticipated to grow from $17.5 billion in 2020 to $33.5 billion by 2025, primarily driven by advancements in materials like polyimide and polyester, which offer excellent thermal stability and flexibility. Different applications may require specific materials that can withstand varying environmental conditions while maintaining electrical performance.

Another critical factor is the thickness and layout design of the PCB. The thickness of the substrate can impact both the performance and durability of the PCB. Industry benchmarks suggest that a thickness between 0.5 mm and 0.8 mm is often optimal for ensuring reliability in compact devices without compromising flexibility. Additionally, the design process must take into account the complexity of the circuitry and the density of components to maximize space utilization. According to IPC-2223, adopting best practices in layout can enhance signal integrity, ultimately leading to more efficient and dependable products for end-users in electronics.

Comparison of Rigid vs. Flexible PCBs: Performance and Cost Analysis

The evolution of printed circuit boards (PCBs) is significantly influenced by the trend of miniaturization, which promotes efficiency and reliability across various industries. As the demand for compact electronic devices rises, flexible PCBs are emerging as a key player due to their ability to bend and fit into limited spaces while maintaining performance. In contrast, rigid PCBs can be more restrictive in design but often provide stronger support for components. The current rigid flex PCB market in China was valued at approximately USD 3.62 billion in 2024, with an impressive compound annual growth rate (CAGR) of 12.4%, underscoring a strong shift towards flexible solutions.

Tips for selecting the best flexible PCBs for your project include evaluating your specific application requirements, such as operating conditions, space constraints, and performance expectations. It’s crucial to compare the cost versus performance benefits between rigid and flexible designs, as this can greatly affect your project budget and timeline. With the rigid flex PCB market anticipated to grow at a CAGR of 11.70%, understanding these distinctions will aid in making informed decisions that align with future industry trends.

Evaluating Material Properties and Their Impact on PCB Durability and Performance

When choosing flexible printed circuit boards (PCBs) for your project, the evaluation of material properties is crucial for ensuring the durability and performance of the final product. Flexible PCBs are typically made from materials such as polyimide and polyester, both of which have unique benefits. Polyimide offers superior thermal stability and chemical resistance, making it suitable for high-temperature applications, while polyester is more cost-effective and works well in less demanding environments. Understanding the specific requirements of your project will dictate which material is more advantageous for your needs.

In addition to material selection, the thickness and type of copper used in the PCB can significantly influence its durability and functionality. Thicker copper layers enhance the board's ability to withstand mechanical stress and thermal fluctuations, which is critical in dynamic applications. Furthermore, the choice of protective coatings can affect the PCB’s longevity. Selecting coatings that resist moisture, chemicals, and abrasion will further extend the functional life of flexible PCBs. By carefully considering these factors, you can ensure that the flexible PCBs you select will meet the demands of your project effectively.

2025 Flexible PCB Material Properties Comparison

This chart compares the thermal stability of different flexible PCB materials. Polyimide shows the highest thermal stability, making it suitable for high-temperature applications, while PET and FR-4 have lower thermal thresholds.

Future Trends in Flexible PCB Technology: Innovations and Market Growth Projections

The flexible printed circuit board (PCB) industry is poised for significant advancements in the coming years. Innovations in materials, manufacturing techniques, and design capabilities are trendsetters in the realm of flexible PCBs. As consumer demand for lighter, more efficient, and versatile electronic devices escalates, manufacturers are exploring novel polymers and substrate technologies that promise enhanced durability and performance. In addition, advancements in flexible electronics are paving the way for integration in new applications such as wearables, medical devices, and IoT devices.

Tips: When considering flexible PCBs for your project, prioritize the choice of materials based on your specific application’s requirements. Pioneering materials like polyimide provide excellent thermal stability and flexibility. Additionally, keep an eye on the latest trends, as industry projections indicate that emerging technologies could dramatically influence cost-effectiveness and efficiency in production.

The market growth projections for flexible PCBs are equally compelling. Analysts predict a robust expansion driven by rising demand in consumer electronics and automotive sectors. As the technology evolves, designers and engineers need to stay updated on the latest developments to leverage cutting-edge solutions that can lead to more compact and efficient device designs.

Tips: Collaborate closely with PCB manufacturers early in the design phase. This approach can help identify potential design challenges and allow for proper integration of the latest technologies, such as advanced soldering methods or embedded components.

Related Posts

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

Understanding PCB Production: Essential Insights for Future Electronics Innovators

-

Top 5 Benefits of Using Flex Circuit Boards in Modern Electronics

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics

-

Exploring the Future of Electronics: How Flexible Printed Circuit Boards Will Revolutionize device Design in 2024