How to Choose the Right Flex PCB Board for Your Project Needs

In the rapidly evolving world of electronics, selecting the appropriate flex PCB board is crucial for ensuring the success of any project. As technology progresses, engineers and designers find themselves faced with an increasingly diverse range of options to meet specific functional and design requirements. Dr. Emily Garcia, a renowned expert in flexible printed circuit technology, once stated, "The right flex PCB board can significantly enhance the performance and reliability of your device while optimizing space and weight." This underscores the importance of making informed choices in the realm of flex PCB boards.

When considering a flex PCB board for your project, it is essential to assess factors such as material properties, layer count, and manufacturing capabilities. With various options available, selecting the right board can impact the overall efficiency and effectiveness of the final product. Understanding these elements not only aids in fostering innovation but also ensures that your project aligns with industry standards and client expectations. As we delve deeper into the intricacies of flex PCB boards, it becomes evident that thoughtful selection is paramount in revolutionizing the performance of modern electronics.

Understanding the Basics of Flex PCB Technology

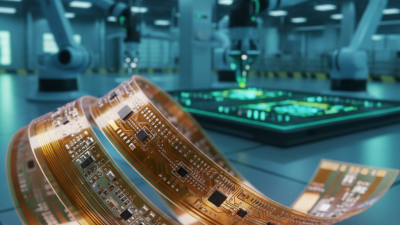

Flex PCB technology has revolutionized the electronics industry by offering a unique solution for designing compact and lightweight devices. At its core, a flexible printed circuit board (Flex PCB) consists of a thin insulating polymer substrate that allows for bending and folding without losing functionality. This characteristic makes it an ideal choice for applications where space is limited or the form factor is irregular, such as in wearable devices, smartphones, and medical equipment. Understanding the fundamentals of this technology is essential for engineers and designers seeking to optimize their projects.

One of the primary advantages of Flex PCBs lies in their ability to integrate components in a three-dimensional space, facilitating complex designs that rigid PCBs cannot accommodate. Additionally, Flex PCBs can improve durability and reduce the risk of mechanical failure since they are less prone to cracking and breaking under stress. Another significant aspect is the potential for cost savings in manufacturing and assembly, as fewer interconnects and connectors are typically required when using flexible circuits. By grasping these foundational elements of Flex PCB technology, stakeholders can make more informed decisions that align with their project requirements and innovations.

Understanding Flex PCB Board Thickness Variations

Identifying Your Project Requirements and Constraints

When selecting the proper flex PCB board for your project, identifying your project requirements and constraints is of utmost importance. Understanding these factors can significantly influence the success of your design and manufacturing process. According to a recent report from the IPC (Institute for Printed Circuits), 70% of PCB failures can be attributed to inadequate specification of project requirements early in the design phase. This statistic underscores the necessity of a meticulous approach to defining what your project demands—be it size, layer count, or material type.

One critical requirement to consider is the environment in which the PCB will operate. Flex PCBs are often used in tight spaces and dynamic applications, which require specific qualities such as flexibility, thermal management, and mechanical stability. A report by the Electronic Industry Association highlights that approximately 60% of engineers encounter issues related to environmental stressors impacting the performance of flexible circuits. Therefore, assessing the expected operational conditions, such as temperature fluctuations and humidity levels, enables you to select materials that can withstand such challenges.

Additionally, taking into account design constraints—like space limitations and integration with other components—is crucial in selecting an appropriate flex PCB that meets both functional and manufacturability standards.

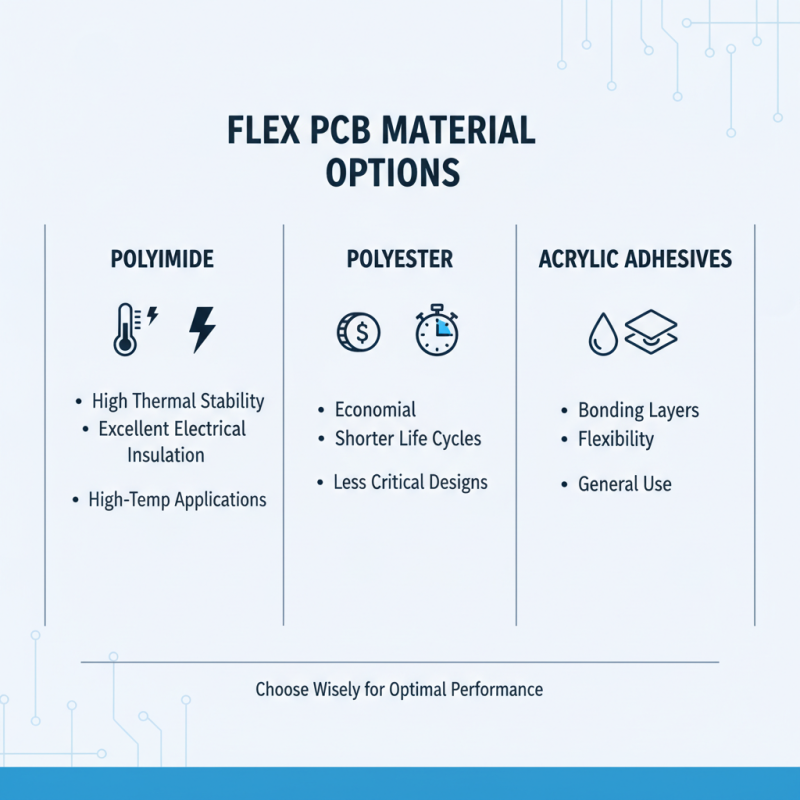

Evaluating Material Options for Flex PCB Design

When selecting a flexible printed circuit board (Flex PCB) for your project, evaluating material options is crucial to ensure optimal performance and functionality. Common materials used in Flex PCB design include polyimide, polyester, and المواصفات. Polyimide is favored for its excellent thermal stability and electrical insulation properties, making it suitable for high-temperature applications. Polyester, on the other hand, is a more economical option, ideal for shorter life cycles and less critical designs.

Tips: When considering materials, assess the environmental conditions your PCB will encounter. If your application involves exposure to extreme temperatures or moisture, opt for materials with higher resistance to these elements.

In addition to temperature resistance, consider flexibility and bend radius. Polyimide offers superior flexibility, which is vital for applications requiring tight bends or complex routing. Ensure the chosen material aligns with the mechanical and electrical demands of your design to avoid issues during operation.

Tips: Test prototypes with different material selections to determine which meets your performance requirements without compromising on quality or durability. Evaluating these factors will play a significant role in the success of your Flex PCB project.

Comparing Manufacturing Processes for Flex PCBs

When selecting a flexible PCB (Printed Circuit Board), understanding the various manufacturing processes is crucial. Flex PCBs are usually manufactured using techniques such as etched copper, printed conductive traces, or even 3D printing. One notable process is the subtractive manufacturing method, where layers of copper are removed from a substrate, allowing for precise designs that reduce material waste. In contrast, the additive process involves building up conductive layers, which can lead to more complex and intricate layouts suitable for modern electronics that demand tighter tolerances.

According to a report by the Flexible Electronics and Displays Industry Association, the flexible printed circuit board market is expected to grow at a CAGR of 10.6% from 2021 to 2026, making it imperative for engineers and designers to choose their manufacturing process wisely. Factors such as flexibility, thickness, and substrate type play crucial roles in this decision. For example, understanding how the different processes will affect the final product's durability and performance is vital for applications ranging from consumer electronics to automotive systems.

**Tips:** When considering your project, assess the specific environmental conditions your PCB will face. Thermal resistance and chemical exposure can differ significantly between manufacturing processes. Moreover, engaging with your manufacturer early in the design phase can uncover insights that may influence material selection, ultimately leading to a more reliable product. Always request samples of each manufacturing method to evaluate their performance in real-world applications.

How to Choose the Right Flex PCB Board for Your Project Needs

| Process Type | Use Cases | Advantages | Disadvantages | Cost |

|---|---|---|---|---|

| Roll-to-Roll | High-volume production, sensors | High efficiency, low waste | Initial setup costs can be high | $0.10 - $0.50 per unit |

| Laser Cutting | Prototype PCB, small batches | High precision, quick turnaround | Higher cost per unit | $1.00 - $3.00 per unit |

| Chemical Etching | Custom designs, electronics | Flexible material options | Longer production times | $0.50 - $2.00 per unit |

| Advanced Printing | Wearable tech, mobile devices | Versatile application, thin profiles | Less suitable for large quantities | $0.75 - $2.50 per unit |

Assessing Performance Factors and Reliability in Flex PCBs

When selecting a flex PCB for your project, it's critical to assess key performance factors and reliability metrics. One of the paramount considerations is the material used in the flex PCB. According to a recent industry report by IPC, materials such as polyimide and polyester have been favored in the market, with polyimide being renowned for its thermal stability and mechanical properties. These materials exhibit a thermal rating of up to 260°C, which is essential for high-performance applications requiring durability at elevated temperatures.

Another crucial factor is the flexibility and bend radius of the PCB. The ability of a flex PCB to endure repeated bending without compromising functionality is vital, especially in applications like wearable electronics and automotive sensors. A study conducted by the FlexTech Alliance indicates that flex PCBs with a bend radius of 5 mm or less can maintain structural integrity over 100,000 cycles, making them suitable for dynamic environments. Additionally, components mounted on flex circuits must also withstand these mechanical stresses, prompting manufacturers to adopt robust soldering techniques to ensure long-term reliability.

Lastly, environmental considerations, such as moisture and chemical resistance, play a significant role in the lifespan of flex PCBs. Research by the Institute of Printed Circuits highlights that PCBs designed with conformal coating exhibit a reduction in failure rates by up to 30% in humid conditions, thus enhancing their operational reliability. By focusing on these performance factors and adopting high-quality materials, engineers can ensure that their flex PCBs meet the demanding needs of modern applications.

Related Posts

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics

-

2025 Guide: How to Choose the Best Flexible PCB Manufacturing Services

-

Top 10 Tips for Choosing the Best Flex PCB Board for Your Project

-

Top 10 Benefits of Using PCB Boards in Electronics Manufacturing

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics