Top 10 Circuit Board Design Tips for Beginners and Experts

When entering the intricate world of circuit board design, both beginners and experts alike can find themselves facing a myriad of challenges. To navigate these complexities successfully, it is essential to adopt effective strategies that enhance both efficiency and functionality. Renowned circuit board expert, Dr. Emily Chen, once stated, "A well-designed circuit board is the backbone of any electronic device; it dictates the performance and reliability of the entire system." Her insights highlight the importance of mastering the fundamentals and implementing best practices in circuit board circuit board design.

As the electronics industry continues to evolve, the demand for innovative and efficient circuit board designs grows. This ever-changing landscape necessitates that designers stay informed about the latest tools, trends, and techniques. Whether you're a novice embarking on your first project or an experienced designer seeking to hone your skills, understanding the core principles of circuit board circuit board design ensures that your creations are both effective and cutting-edge. In this guide, we will explore the top ten tips that will empower you to elevate your design process and achieve exceptional results.

Understanding the Basics of Circuit Board Design for All Skill Levels

Circuit board design is an essential aspect of electronics, serving as the backbone for countless devices. Understanding the basics of circuit board design is crucial for both beginners and experienced professionals alike. According to a report by IPC, a global trade association for the electronics manufacturing industry, nearly 80% of design challenges originated from the schematic design phase, highlighting the importance of mastering foundational skills in this area. For newcomers, grasping concepts like schematic capture, layout principles, and the significance of component placement is vital. These fundamentals not only streamline the design process but also minimize the need for extensive revisions later on.

For seasoned experts, staying updated with the latest trends in circuit board design can significantly enhance project outcomes. The rise of advanced methodologies, such as Design for Reliability (DfR) and Design for Manufacturability (DfM), is reshaping how circuit boards are conceived and produced. Industry data indicates that implementing DfM practices can reduce production costs by up to 30%, reflecting a shift towards more efficient designs. Moreover, understanding the impact of signal integrity and power distribution on performance is essential, as issues in these areas can lead to circuit failures. Ultimately, regardless of skill level, continuous learning and adaptation to emerging technologies are key to creating successful circuit boards.

Essential Tools and Software for Effective Circuit Board Design

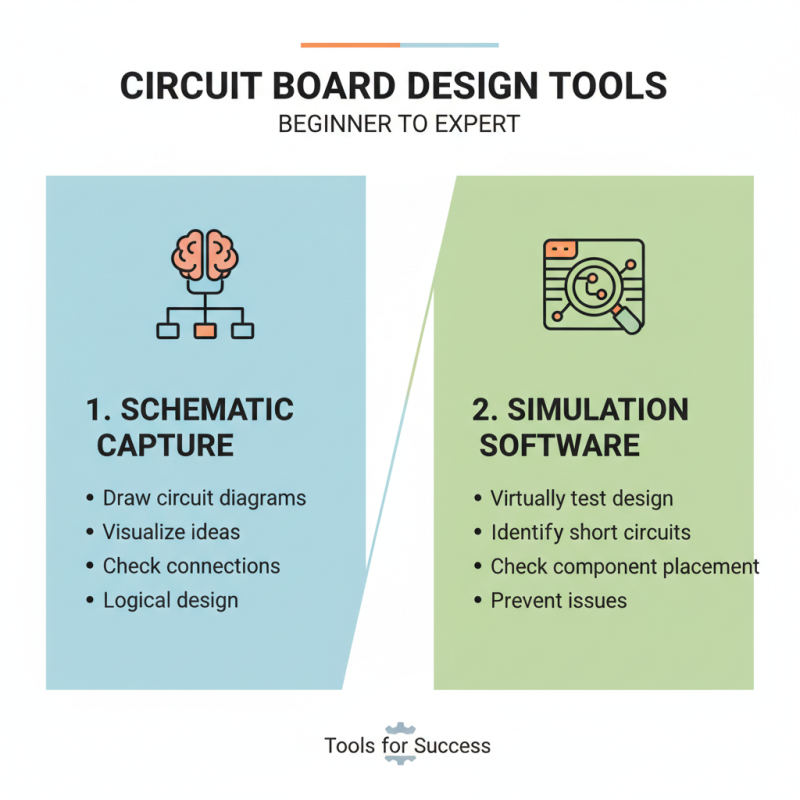

When it comes to effective circuit board design, having the right tools and software makes all the difference, whether you're a beginner or an expert. First and foremost, a good schematic capture tool is essential for translating your ideas into a visual representation. This tool allows users to draw circuit diagrams and check connections, ensuring that the design is logical before moving on to the layout phase. Additionally, simulation software can help test the design virtually, identifying potential issues such as short circuits or incorrect component placements.

Alongside these fundamental tools, a robust Printed Circuit Board (PCB) design software suite is vital. These programs often come equipped with integrated design rule checks, which allow you to adhere strictly to manufacturing standards and specifications. Moreover, having access to libraries of components can streamline the design process, enabling quick placement and modification of parts. Lastly, a reliable collaboration tool is beneficial for teams working remotely or across different locations, ensuring that feedback can be integrated during the design process promptly. By utilizing these essential tools and software effectively, designers can improve their workflow, produce high-quality circuit boards, and minimize costly errors.

Key Design Principles to Optimize PCB Layout and Functionality

When it comes to optimizing PCB layout and functionality, understanding key design principles is essential for both beginners and experts. One crucial aspect is adhering to proper spacing and clearance guidelines. According to a report by IPC, improper spacing can lead to issues such as signal interference and electromagnetic compatibility (EMC) problems. Designers should ensure that traces are adequately spaced to minimize crosstalk and perform thorough ground plane implementations to maintain signal integrity. The IPC-2221A standard suggests maintaining a minimum trace width to clearance ratio, which significantly impacts the performance and reliability of the circuit.

Another fundamental principle is the strategic placement of components on the PCB. The layout should prioritize the flow of signals and power distribution, as well as facilitate effective thermal management. A research study published in the Journal of Electronic Materials indicates that 50% of PCB failures can be attributed to poor thermal management, underscoring the importance of component placement. By positioning heat-sensitive components away from heat sources and ensuring proper ventilation, designers can improve both the durability and efficiency of the circuit. Additionally, employing simulation software early in the design phase can help identify potential layout issues, ensuring that the final product meets performance expectations and reduces time-to-market.

Top 10 Circuit Board Design Tips for Beginners and Experts - Key Design Principles to Optimize PCB Layout and Functionality

| Tip Number | Design Tip | Description |

|---|---|---|

| 1 | Keep Your Layout Simple | Minimize complexity to reduce manufacturing errors and costs. |

| 2 | Use Ground Planes | Implement ground planes to minimize electromagnetic interference and improve signal integrity. |

| 3 | Optimize Component Placement | Place components strategically to reduce trace lengths and enhance performance. |

| 4 | Plan for Thermal Management | Design for adequate heat dissipation to prevent overheating and ensure reliability. |

| 5 | Use the Right Trace Width | Select appropriate trace widths based on the current they will carry to prevent overheating. |

| 6 | Design for Testability | Incorporate test points to ease debugging and troubleshooting of the PCB. |

| 7 | Ensure Good Signal Integrity | Maintain short, direct signal paths and avoid sharp angles in traces. |

| 8 | Use Design Rules Checking (DRC) | Utilize software tools to verify design compliance with manufacturing specifications. |

| 9 | Include Decoupling Capacitors | Place capacitors near ICs to stabilize power supply and reduce noise. |

| 10 | Review and Revise | Regularly review designs for improvements and ensure documentation is up to date. |

Common Mistakes to Avoid When Designing Circuit Boards

When embarking on circuit board design, understanding common mistakes can significantly enhance both the learning curve for beginners and the efficiency for seasoned experts. One frequent error is the neglect of proper component placement, which can lead to signal integrity issues and difficulties in assembly. It's essential to strategically place components to minimize trace lengths and avoid interference, thereby improving the overall performance of the circuit board.

Another common pitfall is underestimating the importance of design rules and guidelines. Failing to adhere to these can result in boards that are not manufacturable or that perform poorly. By integrating design rule checks (DRC) throughout the design process, designers can catch errors early and ensure that their boards meet both functionality and manufacturability standards.

Moreover, overlooking thermal management is a mistake that often goes unnoticed. High temperatures can lead to component failure and affect the overall reliability of the circuit. Designers should consider the thermal profile of each component and incorporate adequate heat dissipation methods, such as heatsinks or strategically placed vias, to ensure longevity and performance. These tips not only help avoid common pitfalls but also pave the way for more successful circuit board designs.

Tips for Testing and Iterating Your Circuit Board Designs

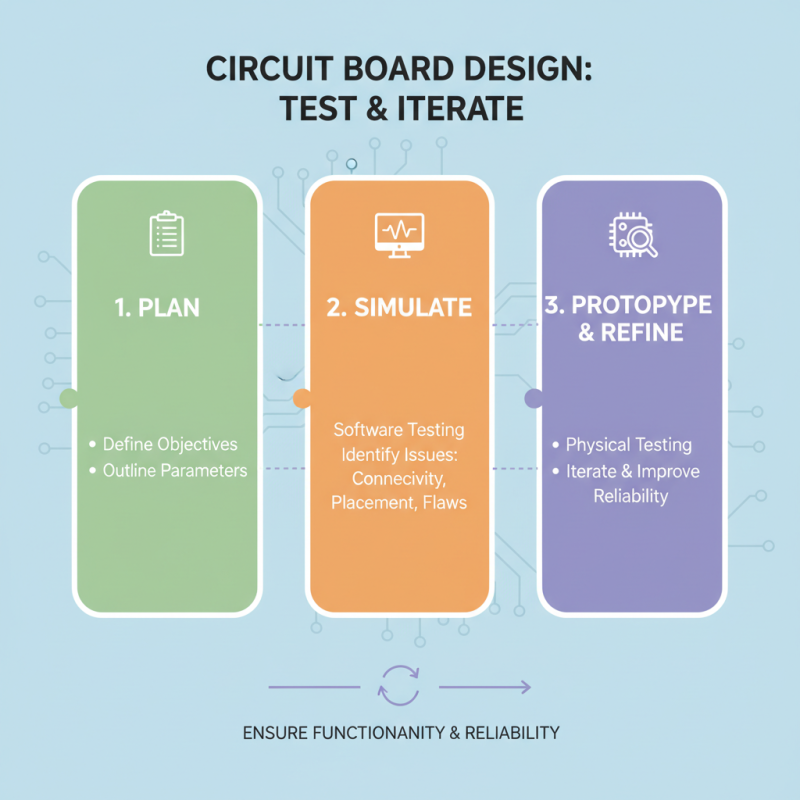

Testing and iterating your circuit board designs is essential for ensuring functionality and reliability. Begin with a clear testing plan that outlines your objectives and the specific parameters you need to measure. Use simulation software to test the theoretical aspects of your design before producing physical prototypes. This step can help identify potential issues in circuit connectivity, component placement, and overall design flaws, saving time and resources down the line.

Once you have a prototype, implement both functional tests and stress tests to assess the performance under various conditions. Evaluate the circuit board's response to temperature changes, load variations, and environmental factors. Gather data from these tests to identify weaknesses or areas for improvement. Iteration is crucial; refine your design based on testing results, making adjustments to component selection, layout, or connections as necessary. Document each iteration thoroughly, as this will provide valuable insights for future projects and help streamline your design process.

Related Posts

-

What is Circuit Board Design and How to Get Started with It

-

10 Essential Tips for Understanding Circuit Boards and Their Functionality

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics