What is Circuit Board Manufacturing? A Comprehensive Guide for Beginners

In the rapidly evolving world of electronics, understanding the intricate process of circuit board manufacturing is essential for anyone looking to delve into this vital industry. Experts like Dr. Emily Chen, a prominent figure in circuit design and manufacturing, emphasize the significance of this field by stating, "The quality and complexity of a circuit board can deeply influence the performance and reliability of electronic devices." This highlights the crucial role that circuit boards play in the functionality of everything from smartphones to medical equipment.

As we explore circuit board manufacturing, it is important to recognize the various steps involved, from initial design and prototyping to the final assembly and testing. Each stage contributes to ensuring that the final product meets industry standards and consumer expectations. With technology advancing at a breakneck pace, staying informed about the latest trends and techniques in circuit board manufacturing is more important than ever.

For beginners aiming to grasp the fundamental concepts of circuit board manufacturing, this comprehensive guide will provide a solid foundation, outlining the key processes, materials, and challenges within the industry. Understanding these elements will not only enhance your knowledge but also prepare you for future advancements in an ever-demanding market.

Understanding the Basics of Circuit Board Manufacturing for Beginners

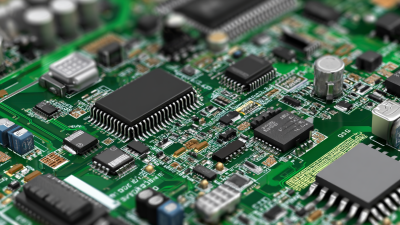

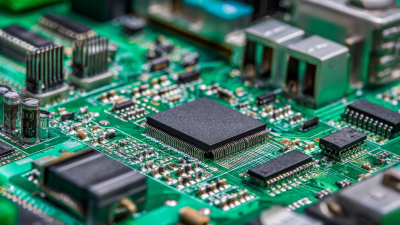

Circuit board manufacturing is a crucial process in the electronics industry, serving as the foundation for a wide array of devices, from smartphones to complex industrial machinery. Understanding the basics of this process is essential for beginners who wish to delve into electronics or manufacturing. At its core, circuit board manufacturing involves several key steps, including designing the layout, etching the conductive pathways, and assembling electronic components onto the board.

The initial stage begins with designing the circuit board layout using specialized software. This design dictates the arrangement of the electrical components and the routing of pathways that connect them. Once the design is finalized, the next step is etching, where copper sheets are used to create the conductive paths. Afterward, components such as resistors, capacitors, and integrated circuits are soldered onto the board. Each of these steps requires precision and an understanding of electrical engineering principles, making it imperative for newcomers to grasp the terminology and techniques involved in circuit board manufacturing.

Key Steps in the Circuit Board Production Process Explained

The circuit board production process encompasses several key steps essential for crafting high-quality printed circuit boards (PCBs). Initially, the design phase involves creating detailed schematics and layout diagrams, which guide the manufacturing process. Once the designs are finalized, the fabrication stage begins, where raw materials such as copper-clad laminate are transformed into the base of the PCB. This phase includes processes like etching, drilling, and plating, which are critical for establishing the electrical pathways and component placements on the board.

Advancements in technology have significantly influenced these steps, particularly with the introduction of automated drilling machines that utilize AI for path optimization. This innovation improves precision and efficiency, addressing common challenges in PCB manufacturing. Furthermore, the trend towards sustainable additive manufacturing practices is emerging, promising reductions in costs and environmental impact. As the demand for complex and high-performance circuit boards continues to rise, understanding these key production steps is vital for businesses aiming to thrive in the competitive landscape of electronics manufacturing.

Essential Tools and Equipment Used in Circuit Board Manufacturing

Circuit board manufacturing is a complex process that requires a range of essential tools and equipment to ensure quality and efficiency. Key components in this process include photolithography systems, which allow for the precise transfer of circuit patterns onto the board surfaces. This is crucial for creating intricate designs that modern electronic devices demand. Additionally, automatic pick-and-place machines help in the accurate placement of components onto the boards, significantly speeding up production times while minimizing errors.

Moreover, advancements in PCB design software have revolutionized the industry, allowing manufacturers to innovate and optimize designs for various applications, including consumer electronics, automotive, and medical devices. The integration of artificial intelligence in design processes is also emerging, enhancing the ability to create rapid prototypes and thus addressing the growing demand for customized solutions.

As the PCB market continues to expand, driven by technological advancements and increased electronic product diversity, the tools and equipment used in manufacturing will evolve to meet these changing needs.

Common Materials Utilized in Circuit Board Fabrication

In circuit board manufacturing, various materials play a crucial role in determining the performance and reliability of the final product. One of the most commonly used materials is epoxy resin, which serves as an insulating layer. This resin not only provides electrical insulation but also contributes to the physical strength of the circuit board. Additionally, fiberglass is often incorporated as it enhances durability and thermal stability, making the boards resistant to environmental stressors.

Another key material is copper, which is used for the conductive pathways. Copper layers are applied to both sides of the board, allowing for efficient electrical connectivity among the components. The thickness of these copper layers can vary depending on the application, which further influences the board's current-carrying capacity. Other materials, such as polyimide and ceramic, are utilized for specialized applications, particularly where high temperatures or specific electrical properties are required. Each material selected for circuit board fabrication plays a pivotal role in optimizing performance and ensuring longevity in various electronic devices.

Common Materials Utilized in Circuit Board Fabrication

This bar chart illustrates the common materials utilized in circuit board fabrication and their respective usage percentages. FR-4 is the most prevalent material, followed by CEM-1 and CEM-3.

Future Trends and Innovations in Circuit Board Manufacturing by 2025

The global printed circuit board (PCB) market is poised for significant growth, with a projected valuation of $715.7 billion in 2024. By 2025, this figure is expected to rise to $741.2 billion, demonstrating a robust compound annual growth rate (CAGR) of over 5.3%. This expansion is primarily driven by the rapid adoption of 5G infrastructure and the increasing demand for high-density interconnect (HDI) boards, responding to the burgeoning electronics and automotive sectors. As the industry embraces digital transformation trends, the necessity for advanced PCBs has never been greater.

Moreover, the industry is witnessing a transformation fueled by artificial intelligence (AI) technologies, which are elevating the demand for high-end PCB products. Innovations in manufacturing processes and materials will play a crucial role in meeting this demand. By 2032, the market is projected to exceed $1.13 trillion, highlighting the accelerated pace of development and investment in the PCB manufacturing sector. Events like the CPCA Show Plus and NEPCON ASIA 2025 signify the convergence of leading manufacturers and technological advancements, setting the stage for a new era in circuit board innovation.

Related Posts

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

What is Circuit Board Design and How to Get Started with It

-

Top 7 Most Innovative Techniques in Circuit Board Production You Need to Know

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies