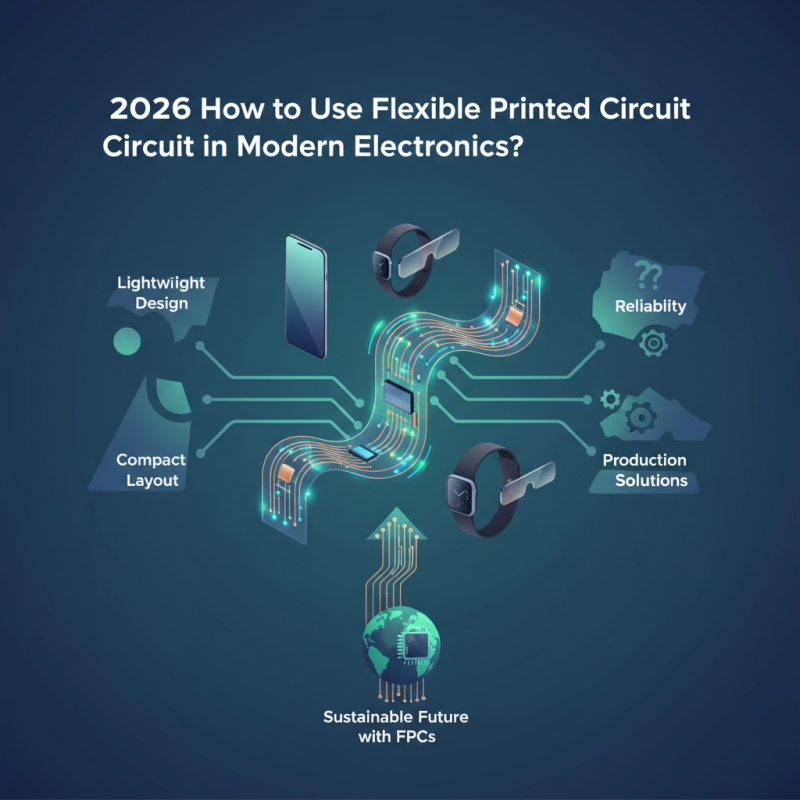

2026 How to Use Flexible Printed Circuit in Modern Electronics?

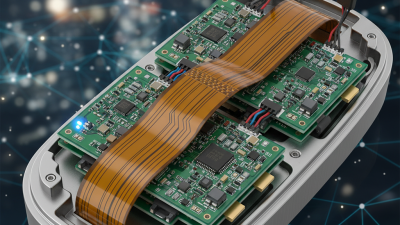

In the rapidly evolving landscape of modern electronics, the use of flexible printed circuits (FPCs) has become essential. These circuits offer unprecedented design possibilities and efficiency. Dr. Emily Chen, a leading expert in flexible electronics, asserts, "Flexible printed circuits can revolutionize device design and functionality." Her insights highlight the transformative potential of FPCs in various applications.

Flexible printed circuits enable lightweight designs and compact layouts. They are increasingly found in devices like smartphones and wearables. Manufacturers appreciate their adaptability. However, challenges remain. Companies face issues with reliability and production costs when transitioning to FPCs. These hurdles require careful consideration and innovative solutions.

As the demand for thinner, more efficient devices grows, flexible printed circuits are critical. Despite the advantages, the industry must reflect on the ongoing need for technological advancements. Building a sustainable future with FPCs involves addressing existing limitations. The journey is complex, yet the promise of flexible printed circuits is undeniable.

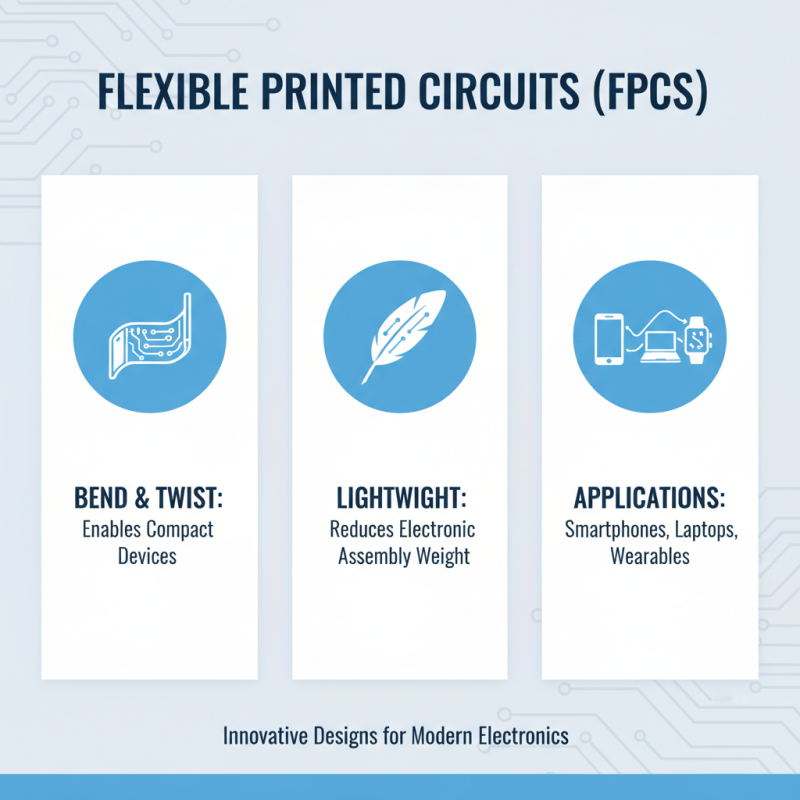

Understanding Flexible Printed Circuits (FPC) in Modern Electronics

Flexible Printed Circuits (FPC) are transforming modern electronics. They offer unique advantages over traditional rigid circuits. Their ability to bend, fold, and fit into compact spaces makes them invaluable in today’s design landscape. These circuits play a crucial role in wearable technology, mobile devices, and even automotive applications.

One notable feature of FPC is their lightweight construction. This significantly reduces the overall weight of devices. However, designers often face challenges with durability. The flexibility can be a double-edged sword; while it allows for intricate designs, it can also make them susceptible to wear and tear. The balance between flexibility and strength is an ongoing consideration.

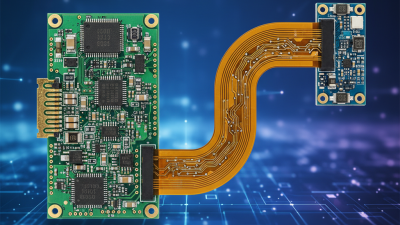

Moreover, the manufacturing process can be complex. Engineers must ensure proper alignment and adhesion of layers. Issues with quality control can arise, leading to potential failures. It’s essential to be mindful of these factors when integrating FPC into new products. Overall, while FPC holds great promise, it requires careful planning and execution.

Key Advantages of Using Flexible Printed Circuits in Devices

Flexible Printed Circuits (FPCs) offer several advantages in modern electronics. They are lightweight and compact. This makes FPCs ideal for portable devices. Many gadgets now require smaller, more efficient components. FPCs fit this demand perfectly. They can bend and twist, allowing for innovative designs. This flexibility often leads to improved performance.

Another key benefit is durability. FPCs can withstand harsh conditions. They resist vibration and shock, which is crucial for electronics used in diverse environments. This durability can lead to longer lifespans of devices. There are also cost advantages. Manufacturing FPCs can reduce assembly costs and improve reliability. However, some challenges remain. The initial production costs can be higher than traditional options.

The integration of FPCs also requires careful planning. Designers must consider the layout and connection points. Not all designs can easily adapt to flexible circuits. Sometimes, the complexity increases with flexibility. Yet, the benefits often outweigh these hurdles. Embracing FPC technology may require a shift in thinking but can yield significant rewards.

Application Areas of Flexible Printed Circuits in Electronics

Flexible printed circuits (FPCs) play a crucial role in modern electronics. They can bend and twist, making them ideal for compact devices. Their lightweight nature helps in reducing the overall weight of electronic assemblies. Common applications include smartphones, laptops, and wearable technology. FPCs enable intricate designs that traditional circuits cannot.

In medical devices, FPCs contribute significantly to miniaturization. These circuits can fit into small gadgets, enhancing patient care. For instance, they are used in portable diagnostic equipment. However, ensuring reliability and durability in various conditions remains a challenge. The design process often requires careful consideration of materials and construction methods.

Despite their benefits, there are limitations. Manufacturing FPCs can be expensive. Quality control is critical to avoid faulty products. Designers must balance cost and performance, which is not always easy. The industry continues to evolve, but improvements are needed to fully harness the potential of flexible printed circuits in electronics.

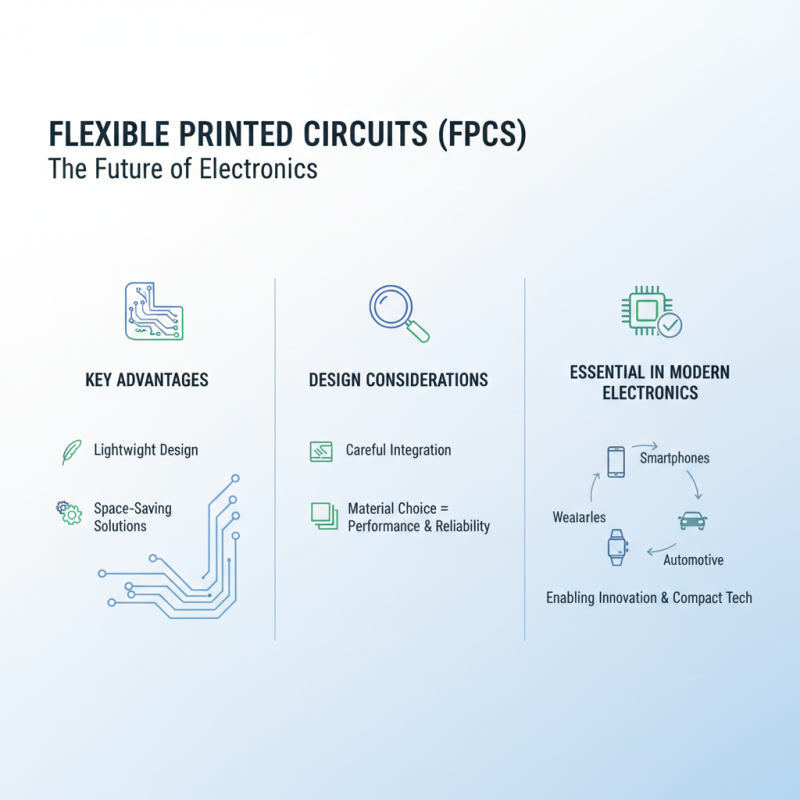

Design Considerations for Implementing Flexible Printed Circuits

Flexible Printed Circuits (FPCs) are becoming essential in modern electronics. They offer unique advantages such as lightweight designs and space-saving solutions. However, integrating FPCs into electronic designs requires careful considerations. The performance and reliability of these circuits depend heavily on the materials used.

For instance, the choice of substrate is critical. Polyimide is popular due to its thermal stability and flexibility. Yet, it can be expensive. Designers often need to balance cost and performance. A recent report indicated that approximately 40% of engineers find material selection challenging. This statistic highlights the need for a deeper understanding of material properties when designing FPCs.

Manufacturing processes also play a significant role. The precision of the photolithography process impacts the final product's quality. Misalignment during production can lead to failures, increasing costs. Many engineers are unaware that even slight variances can cause significant circuit issues. Understanding the manufacturing limitations and tolerances is essential for a successful implementation.

Future Trends and Innovations in Flexible Printed Circuit Technology

Flexible printed circuits (FPCs) are revolutionizing modern electronics. They offer unique solutions for compact designs and intricate layouts. As electronic devices become smaller and more powerful, FPCs fit the bill perfectly. This technology is particularly crucial in wearable devices, smartphone designs, and automotive applications.

In the near future, we can expect innovations in materials and manufacturing processes. New substrates may enhance flexibility and durability. Also, 3D printing technology might enable more complex geometries. There is potential for improved signal integrity and reduced weight. However, challenges still exist, like the cost of advanced materials. Designers must carefully evaluate trade-offs between cost and performance.

**Tips:** Always consider the environment when choosing materials. Sustainability is becoming a priority in electronics. Additionally, stay updated on new manufacturing techniques. They could simplify production and reduce waste. Test prototypes rigorously. Sometimes, what seems ideal on paper might not work in practice.

Future Trends in Flexible Printed Circuit Technology

Related Posts

-

Understanding Rigid Flex PCB Applications and Advantages in Electronics

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

Exploring the Future of Electronics: How Flexible Printed Circuit Boards Will Revolutionize device Design in 2024

-

What is Rigid Flex Rigid PCB and How it Benefits Modern Electronics

-

Top 10 Tips for Choosing the Best Flex PCB Board for Your Project

-

How to Choose the Right Flex PCB Board for Your Project Needs