The Future of PCB Manufacturing Innovations Transforming Electronics Industries

The evolution of PCB manufacturing is at the forefront of transforming the electronics industry, driven by a wave of innovative technologies and methodologies. As highlighted in a recent market report by Research and Markets, the global PCB market is projected to reach $83.21 billion by 2026, growing at a CAGR of 3.62% from 2021. This growth is indicative of the escalating demand for advanced printed circuit boards that cater to the ever-increasing complexity of electronic devices, from smartphones to automotive applications.

Innovations such as 3D printing, automated manufacturing processes, and the integration of IoT technologies are reshaping how PCBs are designed and produced. Furthermore, a study by Smithers Pira predicts that these innovations will significantly reduce production costs and lead times while enhancing product performance. As the electronics sector continues to advance, embracing these PCB manufacturing innovations is crucial for companies seeking to maintain competitiveness in this rapidly evolving landscape.

Emerging Technologies in PCB Manufacturing: Shaping the Future

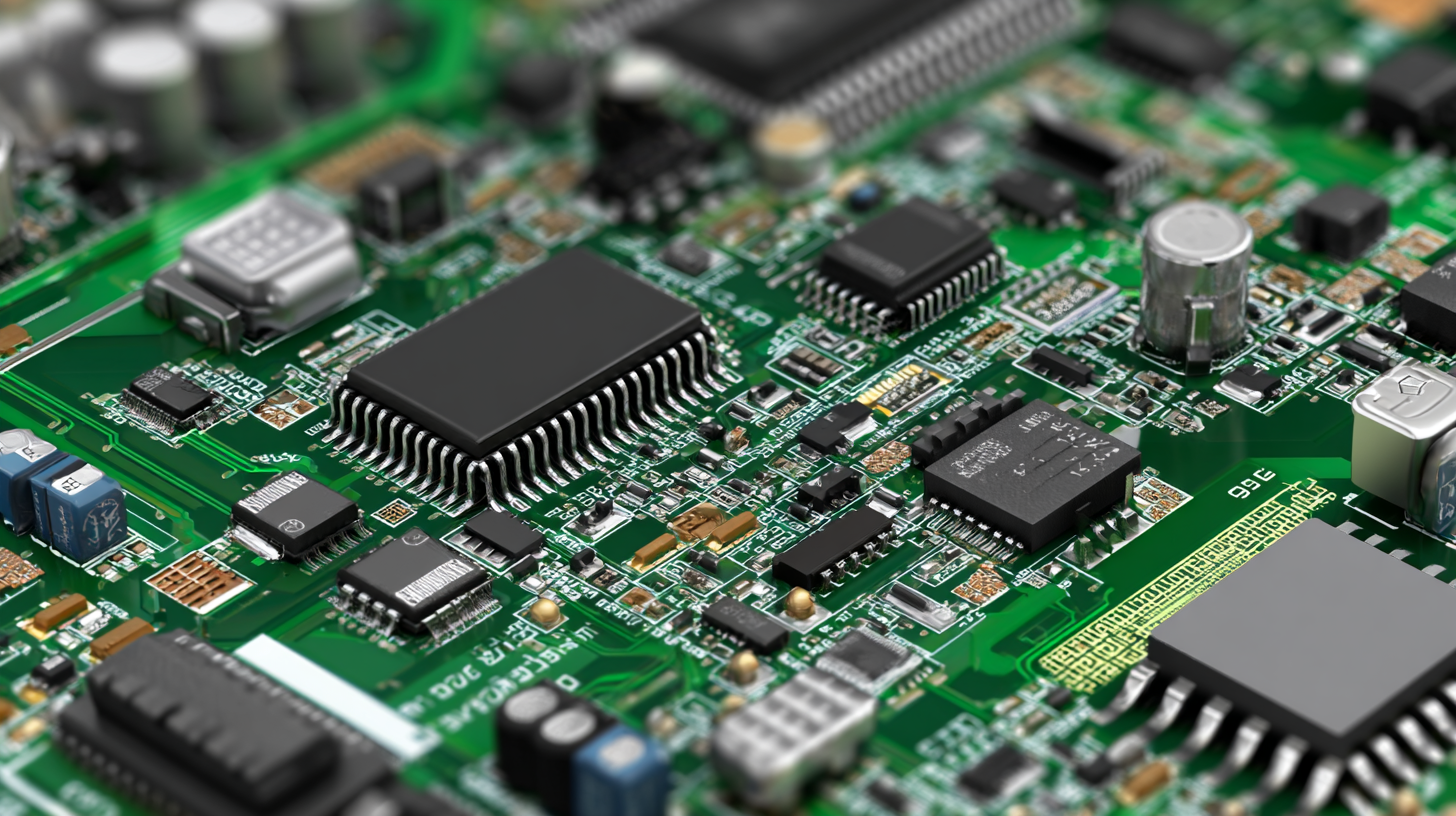

The landscape of PCB manufacturing is evolving rapidly, driven by emerging technologies that are reshaping the electronics industries. Innovations such as additive manufacturing, flexible substrates, and advanced materials are paving the way for more efficient and sustainable production processes. Companies are investing in smart manufacturing techniques and automation to enhance precision and reduce waste during PCB fabrication. These advancements not only improve the overall quality of electronic components but also allow for rapid prototyping and shorter time-to-market.

**Tips:** When considering new PCB technologies for your projects, focus on those that emphasize sustainability. Materials like biodegradable substrates or processes that minimize energy consumption can significantly enhance your product's appeal in an eco-conscious market. Additionally, staying informed about developments in automation can help you identify platforms and tools that will streamline your production while maintaining high standards of quality.

The integration of Internet of Things (IoT) technology into PCB manufacturing is another game-changer, facilitating real-time monitoring and optimization of production lines. This connectivity enables manufacturers to anticipate trends, manage inventory more effectively, and reduce lead times. Moreover, as design complexity increases, leveraging software tools that assist in the PCB design process can ensure that innovations are seamlessly integrated into new products, thus pushing the boundaries of electronics capabilities.

**Tips:** Always keep communication open with your design and production teams. Early collaboration can identify potential challenges and lead to innovative solutions that enhance your PCBs' functionality and performance.

The Future of PCB Manufacturing Innovations

This chart illustrates the adoption rates of various emerging technologies in PCB manufacturing. Automation and IoT Integration are leading the way, while 3D Printing and Advanced Materials also show significant promise in shaping the future of electronics industries.

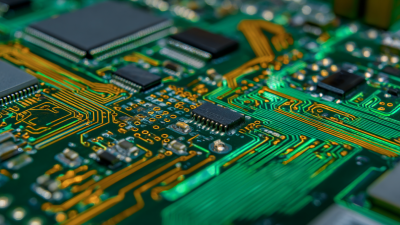

Sustainable Practices in PCB Production: Redefining Industry Standards

Sustainable practices in PCB production are reshaping the electronics industry, driven by increasing environmental awareness and regulatory demands. According to a report by IPC, the global electronics manufacturing services market is expected to reach $1.8 trillion by 2025, with sustainability initiatives becoming a crucial component of this growth. Companies are adopting eco-friendly materials and processes that not only reduce waste but also optimize resource utilization. For instance, the use of lead-free solder and recyclable laminates has become standard in advanced PCB manufacturing, significantly lowering the environmental impact.

Furthermore, the shift towards circular economy principles is gaining momentum, with many manufacturers aiming for zero waste and closed-loop production systems. A study by the Global Electronics Council found that implementing sustainable practices can lead to a reduction in operational costs by up to 30%. This approach not only redefines industry standards but also caters to the rising consumer demand for green electronics. As manufacturers embrace these innovations, the integration of sustainable methodologies is set to redefine the future landscape of PCB production, positioning companies as leaders in both technology and sustainability.

Advancements in Automation: Streamlining PCB Manufacturing Processes

The rapidly evolving landscape of PCB manufacturing is significantly influenced by advancements in automation. By integrating cutting-edge technologies such as robotics, artificial intelligence, and the Internet of Things (IoT), manufacturers are able to streamline processes and enhance productivity. Automated systems can handle repetitive tasks with precision and speed, minimizing human error and reducing production time. This not only lowers operational costs but also allows companies to maintain a consistent quality level across large production runs.

Furthermore, automation facilitates greater flexibility in manufacturing. With the ability to rapidly adjust production lines to accommodate different designs and specifications, companies can respond to changing market demands swiftly. The use of smart machinery equipped with real-time monitoring capabilities enables manufacturers to predict maintenance needs and optimize workflow. This proactive approach to PCB production not only boosts efficiency but also ensures that businesses can swiftly adapt to the fast-paced nature of the electronics industry, setting the stage for future innovations.

The Role of AI and Machine Learning in Enhancing PCB Design

The integration of AI and machine learning into PCB design is revolutionizing the electronics industry, paving the way for smarter and more efficient manufacturing processes. These technologies enable designers to analyze vast amounts of data, optimize layouts, and predict potential issues before they arise. By utilizing algorithms that learn from previous designs, manufacturers can reduce design time significantly, allowing for a quicker turnaround from concept to production.

Tips: When incorporating AI into PCB design, start by selecting the right tools that align with your specific needs. Use simulation software to test various configurations and validate designs before moving to prototyping. Regularly update your AI models with new data to enhance their accuracy and effectiveness.

Moreover, this shift not only enhances design efficiency but also improves overall product quality. Machine learning algorithms can identify patterns that human designers might miss, leading to innovations in circuit performance and reliability. As the technology continues to evolve, we can expect even more groundbreaking solutions that further integrate AI, making PCB manufacturing smarter and more sustainable.

Tips: Engage in continuous learning about AI developments in the electronics sector. Collaborate with other teams to share insights and foster innovation in your PCB design process.

Trends in Miniaturization: Driving Innovations in Electronics Components

The trend of miniaturization in electronics components is revolutionizing the landscape of PCB manufacturing. As consumer demand for smaller, more efficient devices continues to grow, manufacturers are compelled to innovate. This has led to the development of advanced materials and techniques that allow for greater density in component placement, enabling the production of compact and lightweight circuit boards without sacrificing performance. Techniques such as fine-pitch soldering and advanced multilayer designs are now commonplace, paving the way for a new generation of electronic devices.

In addition to enhancing device portability, miniaturization has opened doors to new applications in various industries, including medical technology, automotive, and telecommunications. The ability to integrate more functionality into smaller spaces is particularly crucial in fields like wearable technology, where compactness and efficiency are paramount. As the industry continues to embrace these innovations, we can expect to see a surge in multifunctional devices, driven by cutting-edge PCB design and manufacturing practices that prioritize both size and capability.

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

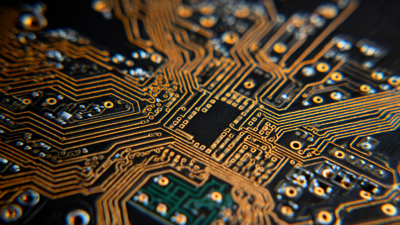

| Innovation Trend | Description | Impact on Electronics | Future Outlook |

|---|---|---|---|

| HDI Circuit Boards | High-Density Interconnect boards utilize microvias to achieve smaller, more efficient designs. | Facilitates the production of compact and lightweight electronic devices. | Expected to grow significantly with the demand for portable technology. |

| Flexible PCBs | Flex circuits can bend and conform to different shapes, paving the way for innovative designs. | Allows for new designs in wearables and medical devices. | The flexible PCB market is anticipated to expand as applications in IoT applications grow. |

| 3D Printing | Utilizing additive manufacturing to create circuit boards layer by layer. | Reduces production time and allows for customization. | The technology is in early stages but shows potential for rapid prototyping. |

| Nanotechnology | The use of nanoparticles to enhance conductivity and reduce size. | Improves performance and reliability of high-frequency applications. | Continuous research is likely to lead to commercial applications. |

| Automated Manufacturing | Integration of robotics and AI in PCB fabrication processes. | Enhances precision and reduces human error, lowering costs. | Predicted to elevate manufacturing efficiency and speed. |

Related Posts

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond