2026 How to Optimize Rigid Flex Circuit Design for Better Performance?

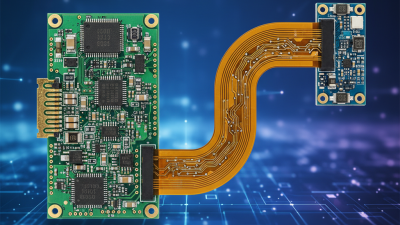

In the rapidly evolving world of electronics, "rigid flex" circuits have emerged as a vital solution. These hybrid circuits combine the best of rigid and flexible technologies. They offer design freedom and improved reliability in various applications. John Smith, a leading expert in circuit design, emphasizes, "Optimizing rigid flex circuits opens new pathways for innovation."

The design of rigid flex circuits presents unique challenges. Engineers must consider factors like material properties, thermal management, and manufacturing processes. Each decision impacts the overall performance. Often, mistakes arise from ignoring these details. These oversights can lead to costly revisions. Therefore, a meticulous approach is crucial.

Constant reflection on design principles can drive improvement. Innovators should analyze past projects to identify what went wrong. Collaboration among teams fosters fresh perspectives. Collectively, they can discover optimization opportunities in rigid flex designs. By embracing imperfections, the industry can pave the way for enhanced performance and greater efficiency in future applications.

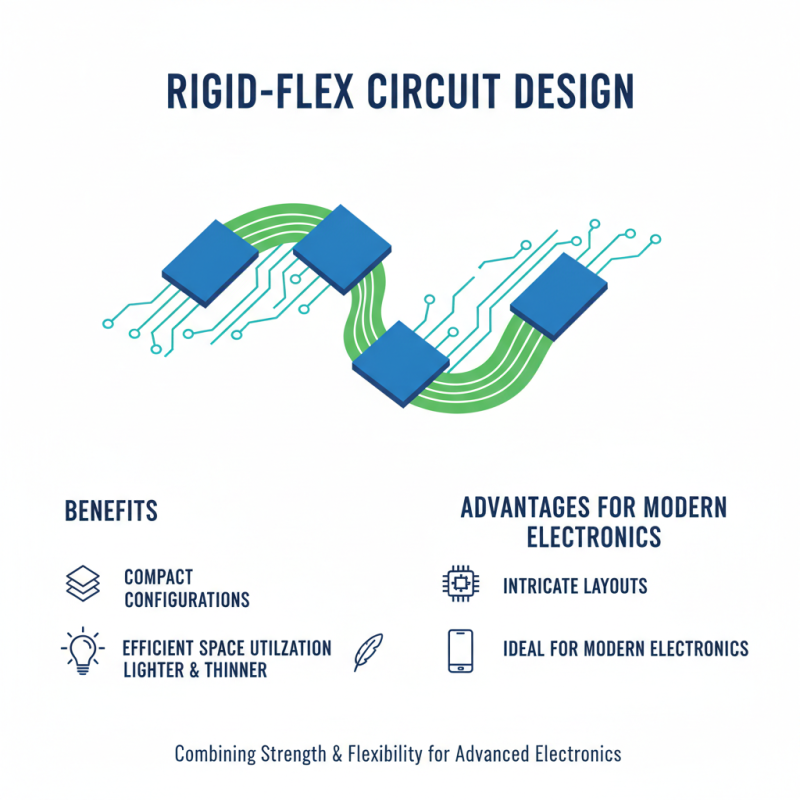

Understanding Rigid Flex Circuit Design: Key Principles and Innovations

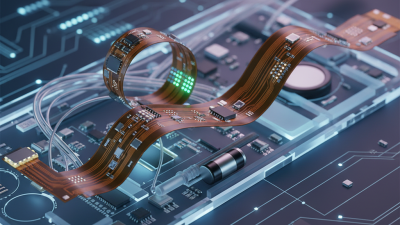

Rigid flex circuit design combines the benefits of both rigid and flexible materials. It allows for compact configurations and efficient use of space. These circuits are lighter and thinner, making them ideal for modern electronics. With this design, manufacturers can create intricate layouts that traditional circuits struggle to achieve.

One key principle is understanding the material choice. The substrate must withstand bending and stretching without cracking. Different thicknesses can affect the performance. Engineers often experiment with various combinations to find the optimal balance between durability and flexibility. Testing these combinations can reveal unexpected challenges, such as inconsistent performance in extreme environments.

Innovations in fabrication techniques are critical. Advanced bonding methods can enhance reliability. However, even the best techniques may not yield perfect results. Engineers must regularly reevaluate their processes. Seeking constant improvement in design can lead to better performance outcomes. It’s a blend of creativity, precision, and sometimes trial and error.

Materials Selection: Optimizing Dielectric and Conductor Choices

When designing rigid flex circuits, material selection is crucial. Dielectric materials impact signal integrity and reliability. Options like polyimide offer great benefits, but they can be costly. Some designs overlook the importance of these choices, leading to performance issues. It's essential to evaluate the trade-offs between performance and cost during the selection process.

Conductor materials also play a significant role. Copper is standard due to its excellent conductivity. However, alternatives like aluminum can reduce costs but may affect performance. Designers must weigh these factors carefully, particularly concerning the layout's complexity. Choosing the right conductor can improve the circuit's overall durability.

Sometimes, the choices made can lead to unexpected difficulties. For instance, a high-frequency application might reveal issues with dielectric loss if the material isn't optimized. Being proactive about these challenges can save time in the testing phase. Reflection on past designs can uncover opportunities for improvement in future projects.

2026 How to Optimize Rigid Flex Circuit Design for Better Performance? - Materials Selection: Optimizing Dielectric and Conductor Choices

| Material Type | Dielectric Constant (εr) | Thermal Conductivity (W/m·K) | Electrical Conductivity (S/m) | Flexibility Rating (1-10) | Cost (per sq. meter) |

|---|---|---|---|---|---|

| Polyimide | 3.0 | 0.12 | 1.0 x 10^6 | 9 | $150 |

| FR-4 | 4.5 | 0.25 | 1.0 x 10^7 | 7 | $50 |

| PTFE | 2.1 | 0.25 | 5.0 x 10^5 | 8 | $200 |

| Polyester | 3.2 | 0.14 | 3.0 x 10^6 | 6 | $70 |

| Epoxy | 4.0 | 0.3 | 2.0 x 10^7 | 5 | $40 |

Layer Stack-up Strategies for Enhanced Signal Integrity and Reduced Noise

When designing rigid flex circuits, layer stack-up strategies play a crucial role in achieving enhanced signal integrity. The arrangement of layers significantly affects how signals travel through the circuit. A well-structured stack-up minimizes crosstalk and electromagnetic interference, which are common issues in complex designs. Maintaining a balanced distribution of ground, power, and signal layers is essential. This creates a more stable environment for signal transmission.

Choosing the right dielectric materials impacts performance as well. Different materials have varying loss characteristics. Consider the thickness and type of the materials used. Thicker layers can provide better insulation but may add weight. The dielectric constant should be low to control signal speed, yet high enough to maintain adequate coupling between layers. An analysis of current flow and potential noise sources can guide these decisions.

It's vital to be aware of the trade-offs in layer design. Overly complicated stack-ups can lead to manufacturing difficulties. Ensuring ease of assembly should not be overlooked. Prototype testing can reveal unexpected issues that need addressing. Designs might meet initial specifications but fail during real-world applications. This process requires continuous evaluation and improvement for optimal results.

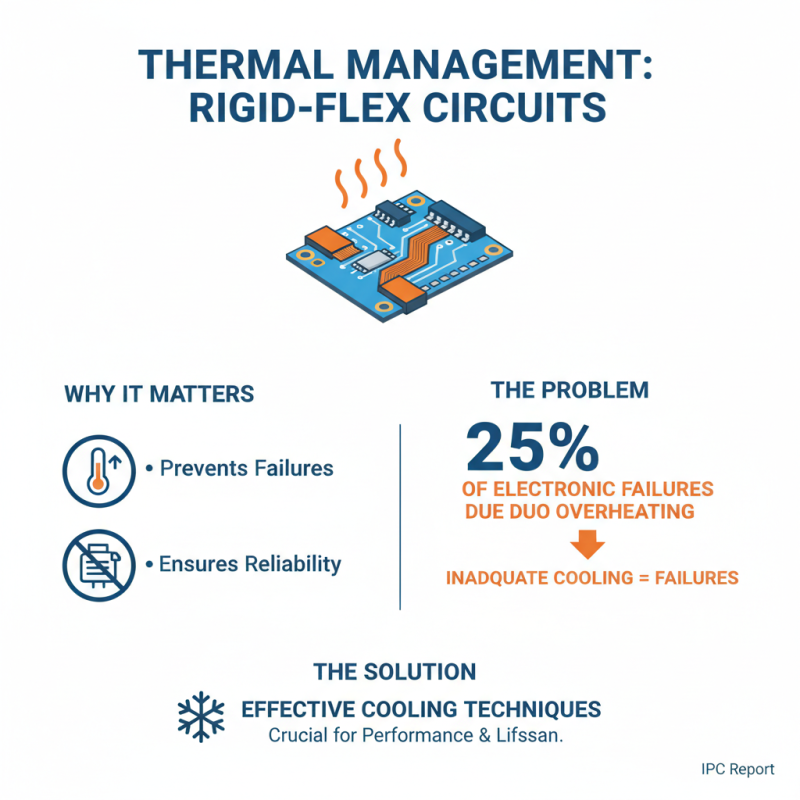

Thermal Management Techniques in Rigid Flex Circuit Applications

Thermal management is crucial in rigid flex circuit applications. Inadequate cooling can lead to failures. A report by IPC states that 25% of electronic failures are due to overheating. This highlights the importance of effective thermal management techniques.

Using materials with high thermal conductivity can significantly improve performance. Copper is commonly used for this reason. Additionally, incorporating heat sinks or thermal vias can dissipate heat more efficiently. Studies show that these techniques can reduce temperature rise by up to 20% in compact designs.

However, not all designs account for thermal expansion. Rigid flex circuits may experience stress from different material properties. This stress can lead to micro-cracks over time. Adapting designs to mitigate these stresses is often overlooked. Understanding the material compatibility is vital. Improved designs can enhance both durability and performance, addressing a critical aspect of circuit design.

Testing and Quality Assurance Metrics for Performance Optimization

When optimizing rigid flex circuit design, testing and quality assurance play crucial roles. Ensuring high performance requires thorough validation of each component. Engineers often overlook this aspect, thinking the design phase is sufficient. However, consistent testing reveals potential issues early on. For example, thermal cycling tests can expose weaknesses before they become critical.

Quality assurance metrics determine the reliability of the entire circuit. Metrics like failure rate and performance consistency provide insight into flaws. Utilizing tools for real-time monitoring can enhance this process. Yet, many teams still rely on outdated methods, leading to gaps in quality controls. Regular reviews of these metrics can highlight discrepancies.

Incorporating feedback loops is vital for continuous improvement. When teams address issues during testing, they can adjust designs accordingly. However, it’s not uncommon for teams to skip this step under tight deadlines. Reflecting on past projects can yield valuable lessons. Prioritizing testing and quality assurance ensures that rigid flex circuits meet performance expectations effectively.

Performance Metrics of Rigid Flex Circuit Design Optimization

Related Posts

-

Understanding Rigid Flex PCB Applications and Advantages in Electronics

-

Top 10 Tips for Choosing the Best Flex PCB Board for Your Project

-

How to Choose the Right Flex PCB Board for Your Project Needs

-

What is a PCB Circuit? Understanding the Basics and Applications Explained

-

What is a Flexible PCB Board and How is it Used?

-

Top 10 Benefits of Using Flexible PCB Boards in Modern Electronics