What is PCB Manufacturing and How Does it Impact Your Electronics Design

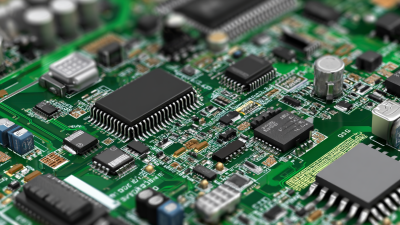

In the world of electronics, the importance of PCB manufacturing cannot be overstated. Printed Circuit Boards (PCBs) serve as the backbone of virtually all electronic devices, providing the necessary connections and supporting components to deliver functionality. According to Dr. Emily Chen, a leading expert in the PCB manufacturing industry, "The quality of the PCB directly influences the performance and reliability of electronic products." Her statement reflects the critical role that PCB manufacturing plays not only in the design process but also in the overall success of electronic innovations.

As the demand for smarter, smaller, and more efficient electronic devices grows, the intricacies of PCB manufacturing become increasingly vital. Understanding the nuances of this process is essential for designers who wish to create cutting-edge products that can compete in a rapidly evolving market. The intersection of PCB manufacturing and electronics design involves meticulous planning, precise engineering, and a keen awareness of emerging technologies that can enhance both performance and manufacturing efficiency.

Through exploring the fundamentals of PCB manufacturing, designers can gain insights into how their decisions can affect the functionality, cost, and longevity of their designs. This understanding paves the way for innovation, ensuring that new electronic products not only meet consumer expectations but also contribute to the advancement of technology as a whole.

Understanding the Basics of PCB Manufacturing Processes

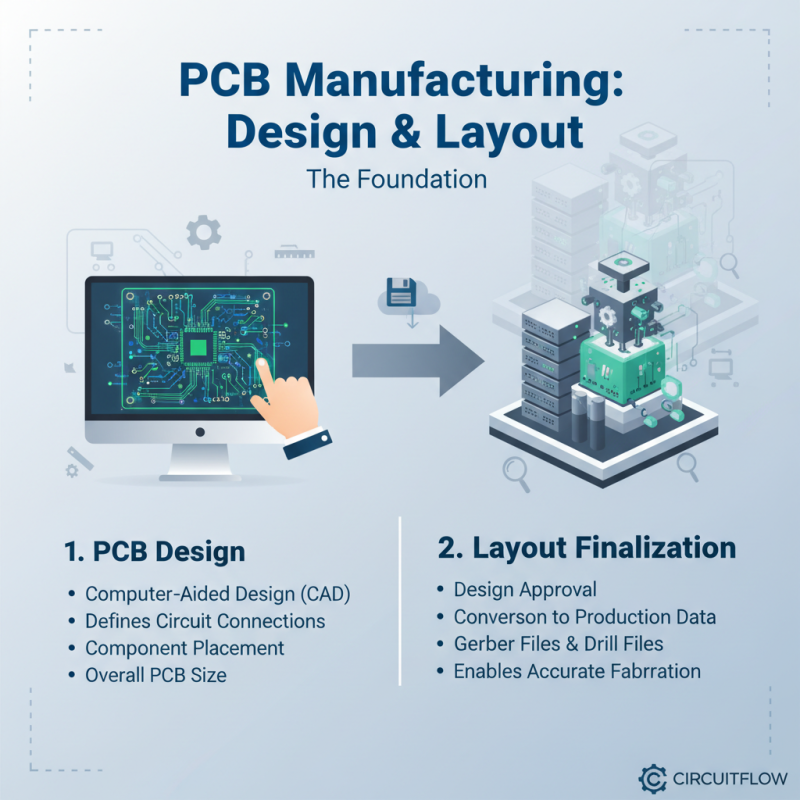

PCB manufacturing is a critical process that involves several stages, each of which plays a significant role in ensuring the final product meets industry standards and performance expectations. The first step typically involves designing the PCB layout using computer-aided design (CAD) software. This layout defines the circuit connections, component placements, and overall size of the PCB, laying the foundation for the entire manufacturing process. Once the design is finalized, it is converted into a format suitable for production, enabling the accurate fabrication of the circuit layers.

After the design stage, the manufacturing process involves several key operations, including etching, drilling, and plating. During etching, unwanted copper is removed from the substrate, leaving behind the desired circuit patterns. Drilling creates holes for component leads and vias, which are essential for connecting different layers of the PCB. Once these processes are complete, solder mask and surface finish applications protect the circuitry and improve solderability. Each step in this process requires meticulous attention to detail, as any errors can impact the functionality and longevity of the electronic device. Thus, understanding the basics of PCB manufacturing processes is essential for effective electronics design.

Key Steps in the PCB Design and Fabrication Workflow

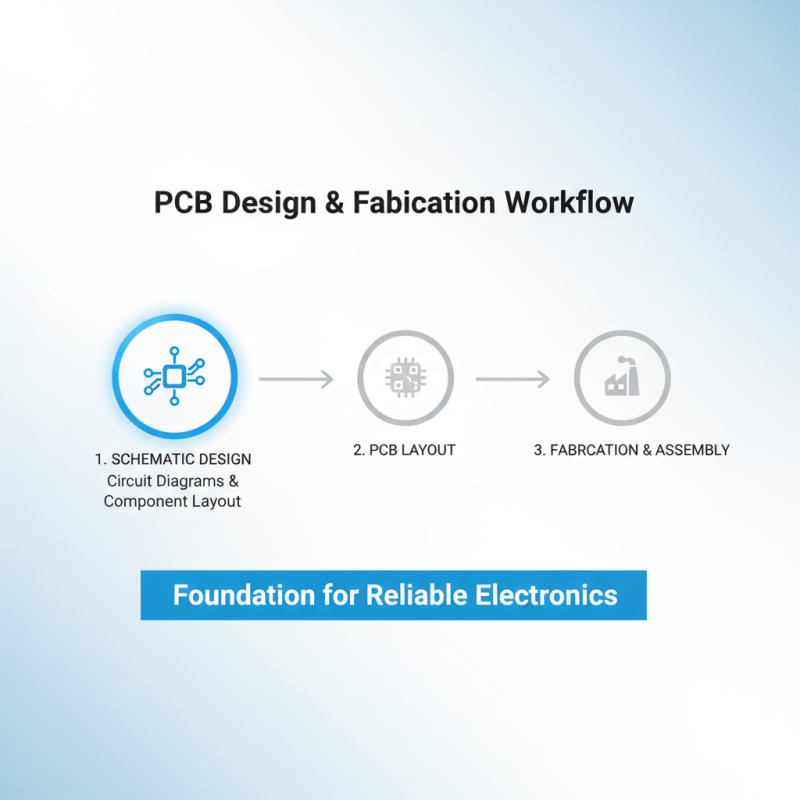

The PCB design and fabrication workflow is a critical process that influences the performance and reliability of electronic devices. The first key step in this workflow is schematic design, where designers create circuit diagrams that outline the electrical connections and components needed for the circuit. This initial stage sets the foundation for the entire manufacturing process, as accurate schematics ensure that the final PCB operates as intended.

Once the schematic is complete, the next step is layout design. During this phase, designers arrange components on a virtual board, meticulously routing traces that connect different parts while considering factors like signal integrity and electromagnetic interference. This layout also includes defining the dimensions and layers of the PCB, as well as creating necessary drill files for component placement. After the layout is finalized, the manufacturing process can begin, which includes steps like etching, drilling, and applying surface finishes to create a functional PCB ready for assembly.

Each of these steps is interconnected and demands precision and attention to detail to ensure that the final product meets performance specifications. Deviations at any stage can lead to malfunctions or inefficiencies in the final electronic product, underscoring the importance of a well-organized PCB design and fabrication workflow.

Materials Used in PCB Manufacturing and Their Impacts

When it comes to PCB (Printed Circuit Board) manufacturing, the choice of materials plays a pivotal role in the performance and reliability of electronic devices. Commonly used materials include FR-4, a glass-reinforced epoxy laminate, which offers excellent electrical insulating properties and thermal stability. Additionally, polyimide is favored for its flexibility and high-temperature resistance, making it ideal for applications requiring bending or high heat. The selection of these materials directly impacts the thermal management, durability, and overall functionality of the final product.

Tips: Always consider the thermal conductivity of the materials you choose; it can significantly influence the performance of high-power electronics. Selecting materials that can effectively dissipate heat ensures the longevity of your devices.

Another important aspect of PCB material selection revolves around the substrate and copper foil thickness. Thinner substrates are beneficial for compact designs, while thicker substrates may provide better mechanical strength. The thickness of copper impacts the current-carrying capacity, which is vital for high-frequency applications. By understanding the implications of these material choices, designers can create more efficient, reliable, and compact electronic products.

Tips: Don’t overlook the environmental impact of your material choices; opting for eco-friendly materials not only aids in sustainability but can also appeal to a growing base of environmentally conscious consumers.

The Role of PCB Design in Electronics Performance and Reliability

PCB design plays a crucial role in determining the performance and reliability of electronic devices. According to a report by IPC, an estimated 70% of failures in electronics can be traced back to issues with the printed circuit board (PCB) design. This can include problems with signal integrity, thermal management, and mechanical stress, all of which are essential for ensuring that the final product operates efficiently and lasts longer. By focusing on effective PCB design, engineers can mitigate potential failures and enhance overall device performance.

Incorporating advanced design techniques such as differential signaling and impedance matching can significantly improve signal integrity, which is vital for high-frequency applications. Furthermore, optimizing the layout to manage heat dissipation effectively ensures that sensitive components operate within safe temperature ranges, reducing the risk of thermal failure. A recent industry study found that designs incorporating proper thermal management not only improve reliability but can also enhance performance by up to 30%.

**Tips:** When designing PCBs, always prioritize a clear layout that minimizes interference and allows for adequate airflow around heat-sensitive components. Additionally, using simulation tools during the design phase can help identify potential issues before production, saving time and resources in the long run. Engaging in regular design reviews with cross-functional teams can also aid in identifying design flaws early in the process, ensuring a more robust final product.

Impact of PCB Design on Electronics Performance

This chart illustrates the various factors in PCB design that contribute to the overall performance and reliability of electronic devices. A higher percentage indicates a greater impact on reliability, emphasizing the importance of each design aspect in ensuring long-lasting and high-performing electronics.

Future Trends in PCB Manufacturing Technology and Its Implications

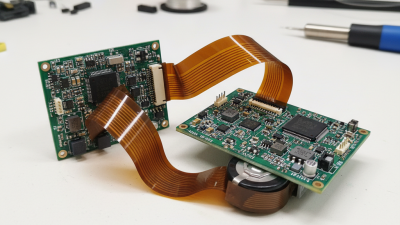

The future of PCB (Printed Circuit Board) manufacturing is set to transform the landscape of electronics design significantly. Emerging technologies such as additive manufacturing, also known as 3D printing, are paving the way for more complex and lightweight PCB designs. This innovation allows for the production of circuit boards with intricate geometries that were previously impossible with traditional subtractive manufacturing. The integration of smart materials and nanotechnology is expected to lead to PCBs that can adapt to their environments, enhancing functionality and efficiency in electronic devices.

As PCB manufacturing technologies continue to evolve, designers must stay informed about these trends. The shift towards automation and the use of artificial intelligence in the manufacturing process can improve both precision and speed, ultimately allowing designers to bring their products to market faster. It's crucial for electronics designers to consider scalability and flexibility in their designs, anticipating future requirements that advanced manufacturing processes can meet.

**Tips:** When designing for future PCB technologies, consider modular designs that can easily adapt to new manufacturing techniques. This adaptability will not only reduce costs but also extend the lifespan of your designs. Additionally, incorporate design for manufacturability (DFM) principles early in the design process to ensure compatibility with emerging PCB technologies. Embracing these trends will position your products at the forefront of innovation in the electronics sector.

What is PCB Manufacturing and How Does it Impact Your Electronics Design - Future Trends in PCB Manufacturing Technology and Its Implications

| Dimension | Current Trends | Future Implications |

|---|---|---|

| Design Complexity | Increased number of layers, tighter tolerances | Need for advanced simulation tools |

| Material Selection | Shift towards eco-friendly materials | Enhanced performance and recyclability |

| Manufacturing Technology | Adoption of automated processes | Increased efficiency and reduced costs |

| Testing and Quality Assurance | More rigorous inspection processes | Greater emphasis on reliability and safety |

| Supply Chain Management | Focus on local sourcing and resilience | Improved agility and flexibility in production |

Related Posts

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Top Reasons to Choose PCB Rigid Flex for Your Next Electronics Project

-

What is Circuit Board Design and How to Get Started with It

-

Top 10 Tips for Choosing the Best Flex PCB Board for Your Project

-

Exploring the Future of Electronics: How Flexible Printed Circuit Boards Will Revolutionize device Design in 2024