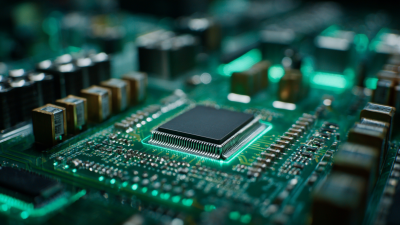

Understanding PCB Production: Essential Insights for Future Electronics Innovators

The rapid advancement of technology has positioned PCB production at the forefront of electronics innovation, making it an essential area of study for future innovators. According to a recent industry report by Research and Markets, the global printed circuit board market is projected to reach USD 88.73 billion by 2026, growing at a CAGR of 4.5% from 2021. This growth underscores the increasing demand for sophisticated electronics across various sectors, including automotive, healthcare, and consumer electronics. As such, understanding the intricacies of PCB production is vital for anyone aspiring to contribute to the next wave of technological breakthroughs.

In the pursuit of more efficient designs and manufacturing processes, PCB production has evolved significantly, incorporating advanced materials and innovative techniques. The use of high-density interconnect (HDI) technology, for instance, has become increasingly prevalent, enabling more compact and efficient circuit designs. According to a report from IPC, HDI boards are anticipated to account for over 25% of the total PCB market by 2025, further highlighting the importance of these technologies in modern electronics. By grasping the essential insights into PCB production, aspiring innovators can better position themselves to harness these trends and make meaningful contributions to the field.

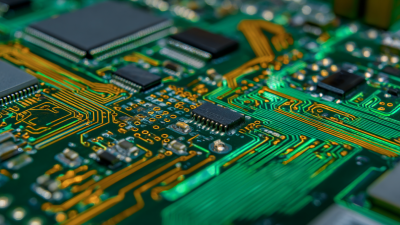

Key Components of PCB Design and Their Impact on Performance

When delving into the key components of PCB design, understanding their impact on performance is paramount for future electronics innovators. Modern advancements, particularly in multi-material 3D and 4D printing, have opened new avenues for integrating innovative technologies into electronic systems. These methods allow for the creation of complex geometries and the potential for improved thermal management, which are critical in the development of high-performance RF components. However, the selection of appropriate materials remains a significant challenge; improper choices can lead to project failures despite superior design.

Moreover, as the industry leans towards greater automation and AI-driven optimization in PCB layouts, engineers must remain cognizant of the compound effects of design decisions on overall performance. The shifting landscape of global supply chains adds another layer of complexity, making it essential for designers to adopt versatile strategies that can mitigate risks associated with economic and geopolitical factors. By comprehensively addressing these components and their implications, future innovators can better navigate the evolving challenges in PCB production and design, fostering advancements in high-speed and compact electronics.

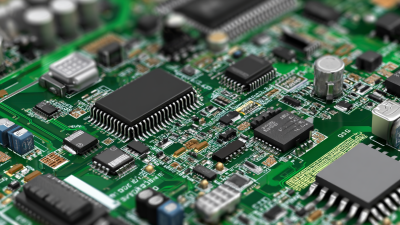

Innovative Materials Transforming PCB Production in the Electronics Industry

The electronics manufacturing industry is on the brink of significant transformation with innovative materials redefining the landscape of PCB production. As the demand for reliable and efficient electronics surges, manufacturers are increasingly turning to advanced materials that enhance performance while reducing environmental impact. According to recent industry reports, the global PCB market is projected to grow at a CAGR of approximately 3.8% from 2022 to 2027, driven by the rising need for electronic devices across sectors.

One crucial trend is the shift towards sustainable materials, as manufacturers recognize the importance of minimizing their ecological footprint. Innovations like biodegradable substrates and recyclable components are gaining traction, enabling companies to meet stringent regulatory standards and embrace eco-friendly practices.

**Tip:** To stay competitive, consider integrating sustainable practices in your production processes. Investing in innovative materials can not only boost your brand’s reputation but also potentially lower costs associated with waste management.

Moreover, the Indian government's recent approval of several electronics component projects highlights the urgent need for MSMEs to leverage such support. This investment can empower local manufacturers to adopt cutting-edge technologies and material science advancements, ultimately enhancing product quality and market competitiveness.

**Tip:** Engaging with startups specializing in new material technologies could provide your business with fresh insights and solutions that align with industry trends.

Understanding PCB Production: Material Innovations Impact

This chart illustrates the trend of different innovative materials used in PCB production over the last five years. The data shows an increasing adoption rate of advanced materials like Flex PCBs and High-Frequency Laminates, which reflect the industry's shift towards more versatile and efficient electronics manufacturing.

Sustainability Practices in PCB Manufacturing for a Greener Future

Sustainability in PCB manufacturing is becoming an essential focus for electronics innovators as the demand for eco-friendly practices continues to rise. Traditional manufacturing processes often involve hazardous materials and generate significant waste, leading to environmental degradation. However, by adopting greener techniques, manufacturers can reduce their carbon footprint and create a more sustainable electronics ecosystem. This includes utilizing materials that are less harmful to both the environment and human health, such as lead-free solder and recyclable substrates.

Sustainability in PCB manufacturing is becoming an essential focus for electronics innovators as the demand for eco-friendly practices continues to rise. Traditional manufacturing processes often involve hazardous materials and generate significant waste, leading to environmental degradation. However, by adopting greener techniques, manufacturers can reduce their carbon footprint and create a more sustainable electronics ecosystem. This includes utilizing materials that are less harmful to both the environment and human health, such as lead-free solder and recyclable substrates.

Moreover, implementing energy-efficient manufacturing processes is crucial for minimizing the environmental impact of PCB production. Innovations such as using renewable energy sources and optimizing manufacturing workflows can result in reduced energy consumption and lower emissions. Furthermore, the incorporation of closed-loop systems allows for the recycling of materials, significantly decreasing waste while fostering a circular economy. By prioritizing sustainability, PCB manufacturers can not only comply with regulatory requirements but also appeal to environmentally conscious consumers, ultimately paving the way for a greener future in electronics innovation.

Emerging Technologies Shaping the Future of PCB Fabrication

Emerging technologies are dramatically transforming the landscape of PCB fabrication, paving the way for innovators in the electronics industry. Among the most significant advancements is the integration of additive manufacturing, or 3D printing, which allows for the fabrication of complex circuit geometries and multi-layered PCBs without traditional constraints. This technique not only reduces material waste but also accelerates prototyping and design iterations, enabling engineers to bring their ideas to life more swiftly and efficiently.

Moreover, advancements in materials science are playing a pivotal role in shaping the future of PCBs. New materials, such as flexible substrates and high-frequency laminates, are enhancing the performance and durability of PCBs in various applications, from consumer electronics to aerospace. The rise of Internet of Things (IoT) devices further drives the demand for smaller, lighter, and more efficient PCB designs, compelling manufacturers to innovate continuously. As these technologies evolve, they create new opportunities for electronics innovators to push the boundaries of what is possible in circuit design and integration.

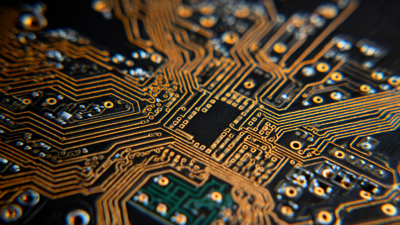

Challenges and Solutions in High-Density PCB Production for Advanced Electronics

As electronics innovation accelerates, understanding the intricacies of PCB production is more crucial than ever, particularly in high-density applications. High-density PCBs present unique challenges, including thermal management, signal integrity, and manufacturability. Industry reports highlight that by 2025, the global PCB market is projected to reach approximately $100 billion, with high-density interconnect (HDI) PCBs leading this growth due to their significance in advanced electronics applications.

To effectively navigate these challenges, manufacturers must adopt advanced fabrication techniques and materials. Utilizing multilayer designs and controlled impedance can significantly enhance performance and reliability. One pivotal trend is the rise of automated production processes, which can improve yields and reduce costs. Furthermore, manufacturers should stay updated on regulatory requirements and environmental impacts, as sustainability becomes a growing concern in electronics manufacturing.

**Tips**:

1. Invest in research and development to explore innovative materials that address thermal and signal integrity issues in high-density applications.

2. Collaborate with startups focusing on automation and AI to optimize production processes and improve overall efficiency.

3. Regularly assess and update your manufacturing technologies to stay aligned with the top trends affecting the electronics industry, ensuring your business remains competitive.

Understanding PCB Production: Essential Insights for Future Electronics Innovators

| Challenge | Description | Solution | Impact |

|---|---|---|---|

| Miniaturization | Designing smaller components while maintaining functionality. | Utilizing advanced simulation software for precise layouts. | Improved product density and reduced weight. |

| Thermal Management | Overheating issues in high-density PCBs. | Implementing advanced cooling solutions and heat sinks. | Enhanced reliability and performance of electronic devices. |

| Signal Integrity | Maintaining signal quality in densely packed PCBs. | Adopting proper routing techniques and differential signaling. | Minimized interference and improved data transmission rates. |

| Manufacturing Tolerances | Difficulty in achieving precise manufacturing specifications. | Utilizing high-precision machinery and automation. | Greater consistency and higher yields in production. |

| Material Selection | Choosing materials that meet electrical and mechanical standards. | Conducting extensive material testing and sourcing options. | Improved product durability and performance. |

Related Posts

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies

-

Understanding Printed PCBs: How Industry Innovations Drive Performance and Efficiency in Electronics

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics