2025's Top 10 Innovations in Circuit Board Design You Can't Miss

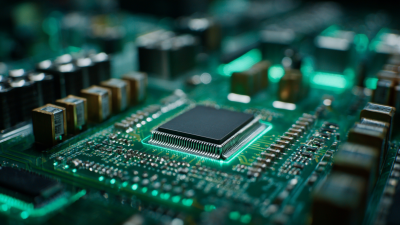

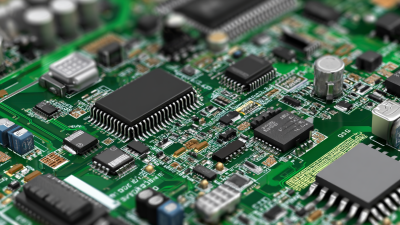

In today's rapidly evolving technology landscape, circuit board design plays a pivotal role in enhancing the performance and efficiency of electronic devices. According to a recent report by Mordor Intelligence, the global printed circuit board (PCB) market size is expected to reach USD 85.06 billion by 2026, growing at a CAGR of 3.85% from 2021 to 2026. This growth signifies not only an increase in demand for circuit board innovations but also highlights the necessity for designers to stay ahead of emerging trends and technologies.

As we approach 2025, several groundbreaking innovations in circuit board design are set to shape the future of the electronics industry. From advancements in flexible PCB technologies to the integration of artificial intelligence and machine learning for optimized design processes, these innovations promise to enhance functionality while reducing production costs. The International Electrotechnical Commission (IEC) forecasts that the increasing complexity of electronic systems will compel designers to adopt more sophisticated design methodologies, making it critical for professionals in the field to be aware of the top trends and solutions available.

In this overview of 2025's top 10 innovations in circuit board design, we will explore key technological advancements that not only cater to the need for smaller, lighter, and more efficient electronic components but also address sustainability concerns, ensuring that the future of circuit board design is both innovative and responsible.

Revolutionary Materials: The Future of Circuit Board Durability and Performance

The future of circuit board design is being reshaped by revolutionary materials that promise enhanced durability and performance. As we look towards 2025, the integration of advanced composites and nanomaterials is set to significantly improve thermal management and mechanical properties. According to a recent industry report by Research and Markets, the global market for circuit board materials is projected to reach $36.2 billion by 2025, highlighting the urgency for innovation in this field.

One notable development is the use of polyimides and thermoplastics, which not only withstand extreme temperatures but also enhance flexibility. These materials can reduce the weight of circuit boards while maintaining reliability and performance. Additionally, the incorporation of graphene—known for its exceptional electrical conductivity—could revolutionize power distribution in electronic devices, making them more efficient.

Tips: When considering material upgrades, it's crucial to evaluate the thermal stability and flexibility of new options. Collaborating with suppliers who specialize in innovative materials can also provide insights into the latest advancements, ensuring that your designs remain at the forefront of technology. Remember, investing in quality materials can lead to long-term performance gains, reducing failure rates over time.

AI-Driven Design Tools: Transforming the Circuit Board Creation Process

The circuit board design landscape is rapidly evolving, with AI-driven design tools leading the charge in revolutionizing how engineers approach the creation process. These innovative tools leverage machine learning algorithms to optimize designs, reduce errors, and expedite production timelines. By analyzing historical data and design patterns, AI can suggest improvements and automate repetitive tasks, freeing designers to focus on more creative aspects of their projects.

**Tips:** When integrating AI-driven tools into your design workflow, start by familiarizing yourself with their capabilities. Explore program-specific tutorials to fully leverage the features these tools offer. Additionally, encourage collaboration among team members to create a diverse pool of insights that can enhance AI-generated suggestions.

Another significant benefit of AI in circuit board design is its ability to enhance simulation accuracy. By utilizing predictive analytics, designers can anticipate potential issues before prototyping, thus minimizing costly revisions. This proactive approach not only streamlines the development process but also leads to higher-quality end products.

**Tips:** Regularly update your toolkits to include the latest AI features, as software providers continuously enhance their offerings. Also, consider setting aside time for team brainstorming sessions to explore new ideas that can be implemented alongside AI suggestions.

3D Printing: Redefining Production Methods for Custom Circuit Boards

3D printing has revolutionized the way we approach circuit board design and manufacturing. As traditional methods often require extensive time and material investment, this innovative technology allows for rapid prototyping and customization. Designers can create intricate geometries and incorporate components directly into the board, enhancing functionality without the need for complex assembly processes. This not only boosts production efficiency but also opens up new possibilities for design creativity.

When considering 3D printing for circuit boards, it's essential to understand the types of materials available and their properties. Tip: Experiment with various polymer blends and composites that can provide the necessary electrical insulation while also offering durability. Pay attention to the printer's resolution and precision, as these factors directly influence the performance and reliability of the printed circuit boards.

Moreover, integrating 3D printing into your workflow can lead to significant cost savings in both time and expenses. Tip: Take advantage of software tools that enable simulation and testing of your designs before printing. This step can prevent costly mistakes and streamline the design process. Embracing 3D printing not only enhances the production of custom circuit boards but also positions your projects at the forefront of innovation.

Flexible and Wearable Technologies: Adapting Circuit Boards for Everyday Use

As we look toward 2025, the integration of flexible and wearable technologies within circuit board design is set to revolutionize everyday devices. These innovations enable circuit boards to be embedded into clothing, accessories, and even directly onto the skin, enhancing user convenience and functionality. The ability to design lightweight, bendable circuits opens up new possibilities for health monitoring, sports tracking, and personal electronics, making technology more accessible and seamlessly integrated into our daily lives.

When considering the adoption of flexible circuit boards, it's essential to focus on materials and manufacturing techniques. Here are some tips to keep in mind: First, choose materials that offer durability and flexibility, such as polyimide and PET films. These materials can withstand bending and stretching without compromising performance. Additionally, ensure that the design incorporates conductive inks or polymers to maintain efficient signal transmission while keeping the boards lightweight.

Another aspect to consider is the user experience. Designs should prioritize comfort and usability, especially for wearable tech. Pay attention to how the circuit board interacts with the user's skin—focusing on hypoallergenic materials and ensuring breathability can significantly enhance the overall experience. By combining innovative design with user-centered thinking, circuit boards can become an integral part of everyday technology.

Eco-Friendly Innovations: Sustainable Practices in Circuit Board Manufacturing

The circuit board design industry has been undergoing significant transformations as sustainability becomes a priority. Eco-friendly innovations are now at the forefront of manufacturing practices, leading to reduced environmental impact. One of the key innovations is the use of biodegradable materials in the production of circuit boards. Manufacturers are exploring organic substrates that can decompose more easily than traditional materials, offering a greener alternative without sacrificing performance.

Additionally, companies are adopting a circular design approach, which promotes recycling and reuse of materials throughout the production process. This includes reclaiming metals and components from old circuit boards, significantly minimizing waste. Some manufacturers are implementing water-based adhesives and low-emission soldering processes, further reducing harmful chemicals released into the environment. These sustainable practices not only help manufacturers meet regulatory standards but also appeal to environmentally conscious consumers looking for greener electronics solutions.

2025's Top 10 Innovations in Circuit Board Design You Can't Miss

This chart displays the innovations in circuit board design focused on sustainability and eco-friendliness that are expected to shape the industry in 2025. The data showcases the projected percentage of adoption of various eco-friendly practices in circuit board manufacturing.

Related Posts

-

Top 7 Most Innovative Techniques in Circuit Board Production You Need to Know

-

Unlocking Innovation: The Future of Circuit Board Design in 2024 and Beyond

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics

-

Unlocking the Future of Circuit Board Production with Sustainable Practices and Advanced Technologies

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries