Top Reasons to Choose PCB Rigid Flex for Your Next Electronics Project

In the rapidly evolving world of electronics, the choice of printed circuit boards (PCBs) plays a crucial role in the performance and durability of devices. Among the various types of PCBs available, "pcb rigid flex" technology stands out for its unique advantages. By combining the features of rigid and flexible PCBs, this innovative solution is transforming the landscape of electronic design. Engineers and designers are increasingly turning to pcb rigid flex for its ability to offer greater design flexibility, enhance reliability, and reduce overall weight in complex electronic applications.

As devices become more compact and multifunctional, the demand for lightweight yet robust circuit boards continues to rise. Pcb rigid flex offers a seamless integration of rigid sections for component mounting and flexible areas for navigating tight spaces, making it an optimal choice for a wide range of industries, from aerospace to consumer electronics. This versatility not only improves the performance of devices but also enables more creative approaches to product design.

Ultimately, choosing pcb rigid flex for your next electronics project can lead to innovative solutions that meet the challenges of modern technology. Whether you're developing wearables, medical devices, or cutting-edge communication tools, understanding the benefits of this advanced PCB technology is essential for achieving success in today's competitive market.

Benefits of Rigid Flex PCBs in Modern Electronics Design

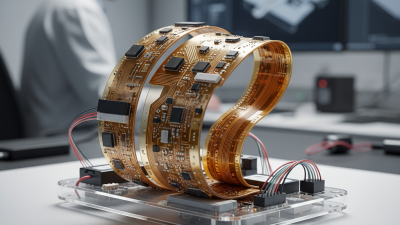

Rigid flex PCBs have become increasingly popular in modern electronics design due to their unique benefits that cater to the demands of contemporary devices. One of the primary advantages is their ability to save space without compromising functionality. Unlike traditional rigid PCBs, rigid flex designs seamlessly integrate multiple layers of circuitry that can be bent and shaped to fit compact spaces, making them ideal for applications in mobile devices, wearables, and other limited-space environments.

In addition to space-saving capabilities, rigid flex PCBs offer enhanced durability and reliability. They can withstand mechanical stress and vibrations better than rigid boards due to their flexibility. This characteristic reduces the risk of physical damage during manufacturing and daily usage, which is crucial for devices that require a longer lifespan. Furthermore, the integration of rigid and flexible elements allows for improved thermal management, ensuring that components function efficiently without overheating, a common issue in densely packed electronic designs. Overall, rigid flex technology not only meets the demands of modern electronics but also elevates the design possibilities for engineers.

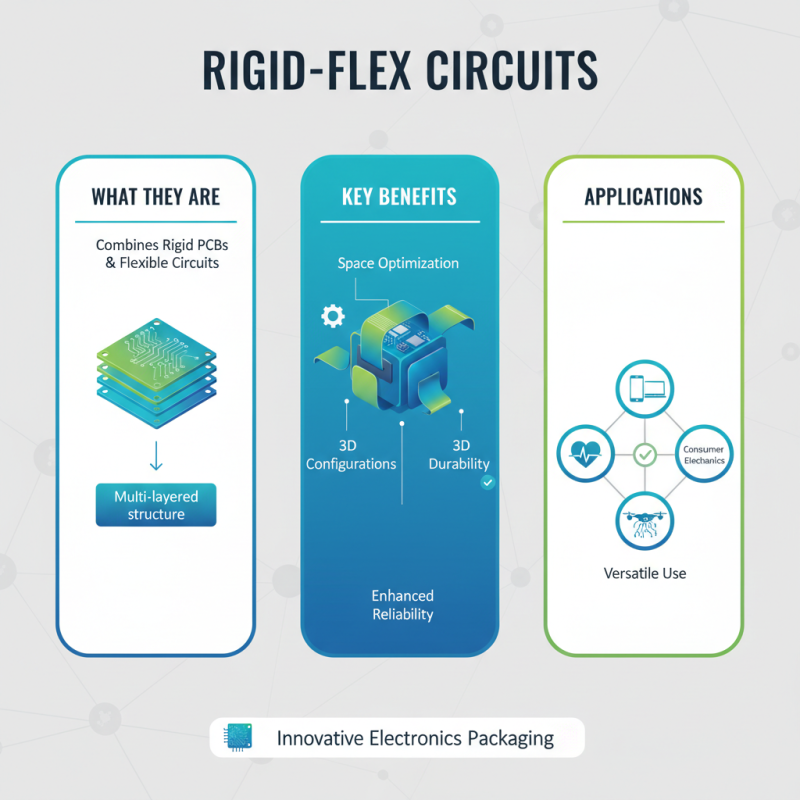

Understanding the Structure and Function of Rigid Flex Circuits

Rigid flex circuits combine the robust properties of rigid printed circuit boards (PCBs) with the flexibility of flexible circuits. This unique structure allows for intricate designs that can fit into compact spaces while maintaining reliability and durability. A rigid flex circuit typically consists of multiple layers of rigid boards connected by flexible substrates, enabling complex three-dimensional configurations. This harmonious integration not only optimizes space but also enhances the functionality of electronic devices across various applications, from consumer electronics to medical devices.

The function of rigid flex circuits is primarily rooted in their versatility. They allow for the integration of various components, such as chips and connectors, in a manner that traditional rigid or flexible circuits cannot achieve alone. With the ability to bend and conform to specific shapes, these circuits reduce the risk of fatigue and damage during use, making them ideal for dynamic environments. Moreover, they facilitate efficient thermal management and signal integrity, essential for the performance of high-speed electronics. Ultimately, understanding the structure and function of rigid flex circuits is crucial for engineers and designers aiming to innovate and overcome the challenges in modern electronic design.

Cost-Effectiveness: Long-Term Savings with Rigid Flex Solutions

When considering PCB design for electronics projects, one of the most compelling advantages of rigid flex solutions is their cost-effectiveness, particularly in the long term. Although the initial investment in rigid flex PCBs may appear higher than traditional rigid or flexible boards, the savings realized over time often outweigh the upfront costs. Rigid flex technology combines the durability of rigid circuits with the adaptability of flexible designs, reducing the need for multiple components and simplifying assembly processes. This integration not only minimizes manufacturing costs but also shortens production timelines.

Additionally, rigid flex solutions can lead to significant savings in maintenance and operational expenditures. Their robust construction reduces the likelihood of failure, which translates to lower repair and replacement costs throughout the product's lifecycle. Moreover, by eliminating connectors and reducing the need for additional hardware, rigid flex designs optimize the overall footprint of the device, making them perfect for compact electronics. This efficiency contributes to enhanced performance and reliability, further securing the cost-effective appeal of rigid flex technology for future projects.

Cost-Effectiveness of Rigid Flex PCBs vs Traditional PCBs

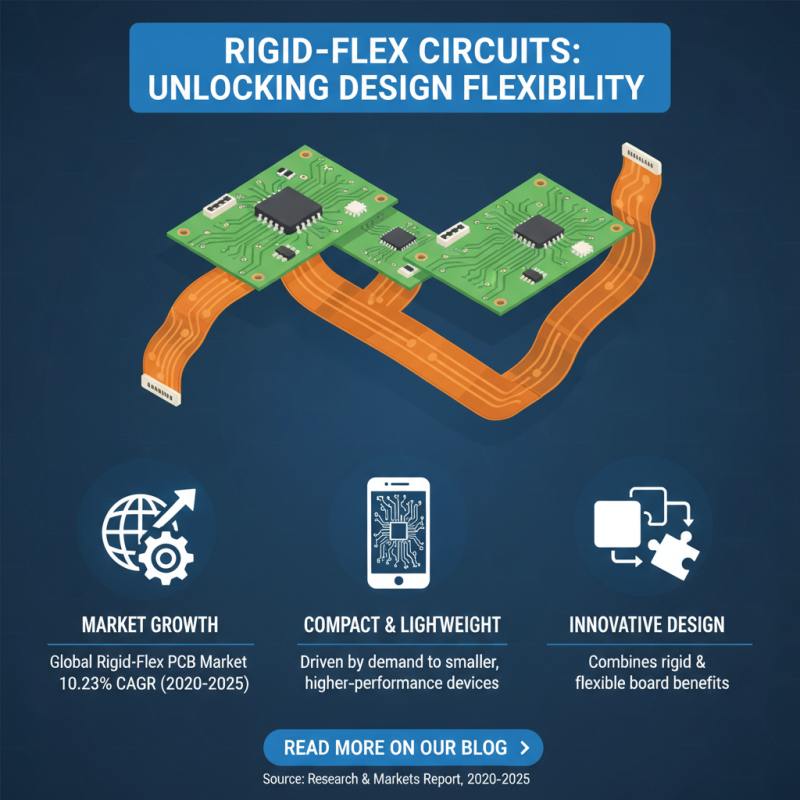

Design Flexibility: How Rigid Flex Enhances Circuit Layouts

Rigid flex circuits have become increasingly popular in the electronics industry due to their ability to enhance design flexibility. According to a report by Research and Markets, the global rigid flex PCB market is expected to grow at a CAGR of 10.23% from 2020 to 2025. This growth is driven by the heightened demand for compact and lightweight electronic devices that do not compromise on performance. Rigid flex designs combine the benefits of both rigid and flexible circuit boards, allowing engineers to create innovative layouts that can efficiently accommodate the shrinking form factors of modern electronic devices.

The integration of rigid flex technology enables designers to optimize circuit layouts by making use of three-dimensional space. This capability is particularly advantageous in applications such as medical devices, aerospace systems, and consumer electronics, where space is at a premium. According to a study published by IPC, 55% of electronics manufacturers cite space constraints as a significant challenge in design. Rigid flex circuits alleviate this issue by allowing for complex geometries without sacrificing durability or performance. By tailoring the circuit structure to fit the specific application, manufacturers can enhance functionality while simultaneously improving reliability, making rigid flex an ideal choice for cutting-edge projects.

Applications and Industries Making Use of Rigid Flex Technology

Rigid-flex technology has become increasingly popular in various applications across multiple industries. This innovative approach combines the best features of both rigid and flexible printed circuit boards (PCBs), providing manufacturers with unparalleled versatility and reliability. Industries such as healthcare utilize rigid-flex PCBs in medical devices, where space and weight are crucial. The compact nature of these boards allows for sophisticated functionality while meeting strict regulatory requirements. Additionally, the aerospace sector benefits significantly from rigid-flex technology, where durability and lightweight designs are essential for high-performance systems.

Tips: When selecting rigid-flex PCBs for your project, consider the environmental factors they will face. Understanding their application requirements can help inform material choice, thus enhancing performance and longevity.

Moreover, consumer electronics are increasingly employing rigid-flex designs to maximize space and improve functionality in compact devices like smartphones and wearables. The ability to conform and adapt to various shapes allows for greater design freedom, leading to innovative product development. Automotive applications are also on the rise, where robust and reliable flexible circuits support advanced driver-assistance systems (ADAS) and infotainment systems.

Tips: Engage with a knowledgeable PCB manufacturer early in the design phase to optimize the layout and ensure that your rigid-flex boards meet all necessary specifications.

Related Posts

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

Top 10 Benefits of Using Flex PCB Boards in Modern Electronics

-

2025 How to Choose the Best Flexible PCBs for Your Project

-

Understanding the Importance of Flexible Printed Circuits in Modern Electronics

-

2025 Trends in Flexible Printed Circuit Boards: Innovations and Applications

-

Revolutionizing Circuit Board Manufacturing: Innovative Techniques for Efficient Production